Product series

Contact us

Phone: +86-5065741650

Manager Wang

Email: 15065709046@163.com

Address: No. 10, District 1, 300 Changjiang Road, Yantai Economic and Technological Development Zone

Wastewater treatment

A technology-based enterprise focusing on industrial gas separation and purification with gas separation membrane as the core technology

- Commodity name: Wastewater treatment

Product details

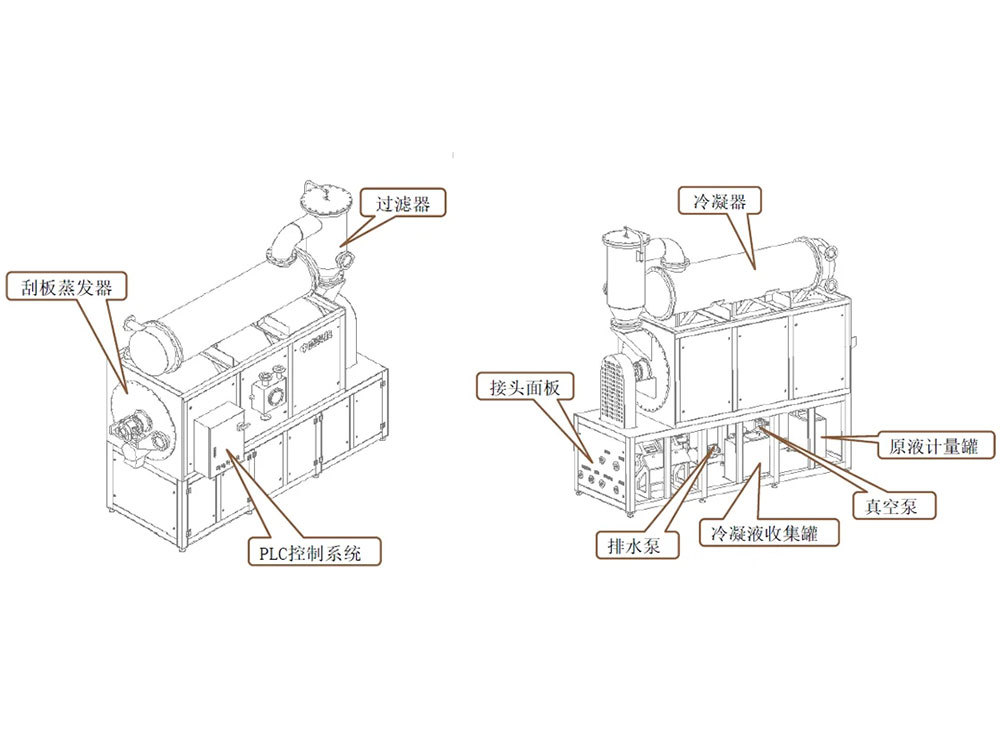

1.1 Wet Oxidation Unit

(1) Technical Introduction

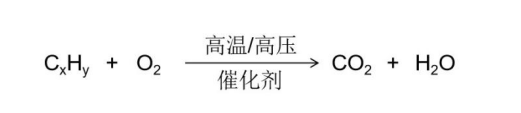

Wet catalytic oxidation (WAO) technology is one of the most actively researched oxidation technologies currently. Under high temperature (125~320℃) and high pressure (0.5~20MPa) conditions, it uses oxygen in the air as an oxidant (sometimes O3, H2O2, etc.) to oxidize and decompose organic matter in wastewater into CO 2 and H 2 O, etc., inorganic substances or small-molecule organic substances.

Because the traditional wet oxidation method has high temperature, high pressure, and long residence time, and the requirements for certain refractory organic matter reactions are harsh, the wet catalytic oxidation method (CWAO) has gradually been developed later.

CWAO adds a suitable catalyst on the basis of WAO to reduce the reaction temperature and pressure, shorten the reaction time, improve the oxidation efficiency, and reduce the cost. Under high temperature (80-180℃), high pressure (1-5 MPa), and the presence of a catalyst, CWAO uses oxygen or air as an oxidant in the liquid phase to oxidize and decompose dissolved or suspended organic matter or reducing inorganic matter in water into harmless substances such as carbon dioxide, water, and nitrogen. CWAO technology has the characteristics of high processing efficiency, short reaction time, fast oxidation speed, and no secondary pollution. Using CWAO to treat chemical wastewater can improve its biodegradability while removing some organic pollutants, which is particularly effective for high-concentration, highly toxic wastewater that inhibits biological methods. Because the reaction is carried out under completely closed conditions, and pollutants are often in the liquid phase, the small amount of gas emitted is mainly oxygen and carbon dioxide, which not only has high economic value but also has high environmental effects.

Catalysts for wet catalytic oxidation generally include three categories: metal salts, oxides, and composite oxides. According to the existence form of the catalyst in the system, wet catalytic oxidation can also be divided into homogeneous wet catalytic oxidation and heterogeneous wet catalytic oxidation. In homogeneous wet catalytic oxidation, the catalyst exists in the form of ions, which is difficult to recover and reuse from wastewater and is prone to secondary pollution. In heterogeneous wet catalytic oxidation, because the solid catalyst does not dissolve and does not lose, activation regeneration and recovery are relatively easy, so the application prospect is broad.

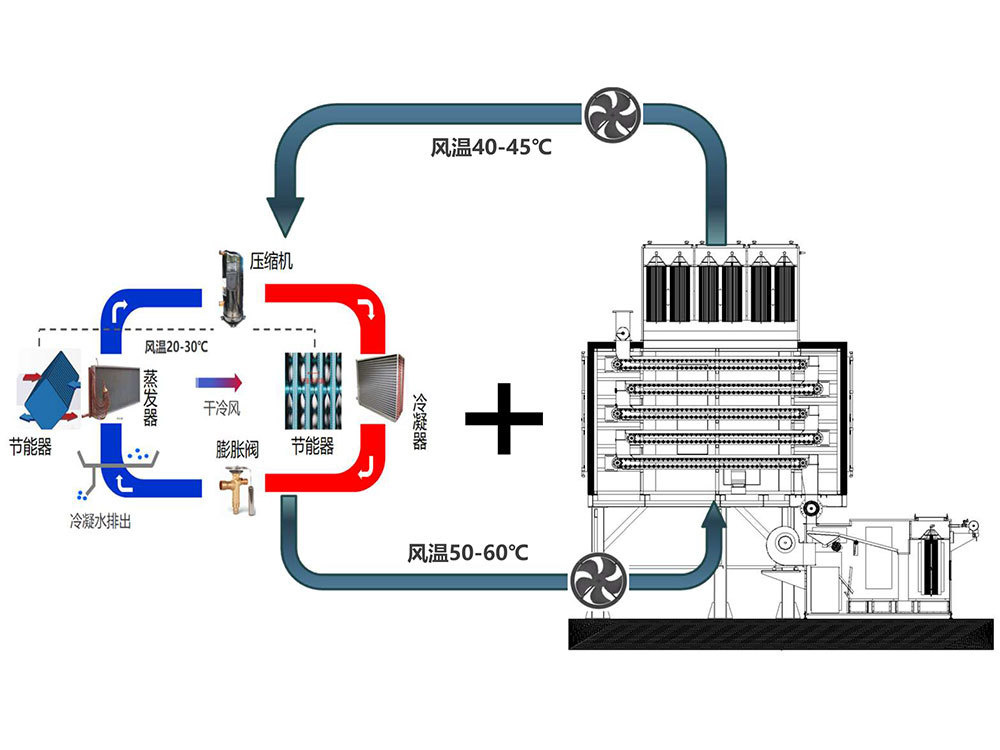

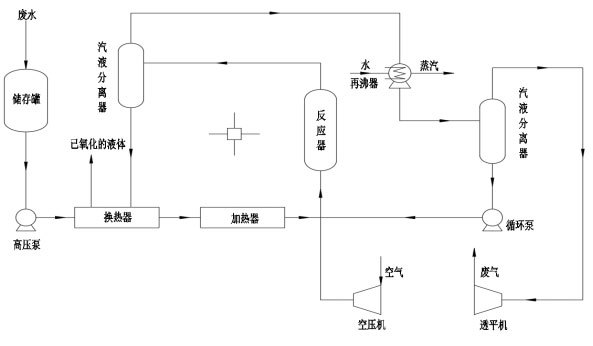

(2) Process Flow

After the wastewater is pressurized by a high-pressure feed pump and mixed with air from the air compressor, it is sent to a heat exchanger to exchange heat with the hot material from the reactor outlet, and then enters a secondary heat exchanger to be heated to the reaction temperature and introduced into the oxidation reactor. The organic matter in the wastewater is oxidized, and the heat released by the reaction keeps the temperature of the mixed liquid constant. The temperature and pressure of the liquid flowing out of the reactor are both high. After gas-liquid separation, the liquid is used to preheat the raw materials. The gas phase contains a large amount of condensable gas, which can be used to prepare low-pressure steam to recover heat, and can also be used for turbine work. Finally, all waste gases are treated by a tail gas absorption tower and discharged into the atmosphere after meeting the standards.

Catalytic wet oxidation process flow

(3) Technical Characteristics

Mild reaction conditions: Compared with conventional WAO technology, CWAO technology requires lower reaction temperature and pressure;

High processing efficiency: CWAO technology can achieve a COD removal rate of over 90% for most organic wastewaters, and the effluent biodegradability is greatly improved;

Small footprint: Compared with traditional biochemical methods, the CWAO device has a smaller footprint, and an 80m 3 /d scale device has a footprint of only 400m 2;

Low energy consumption: The entire CWAO process is integrated and controlled by DCS, and the treatment process can achieve self-heating, with significant energy-saving effects;

Wide range of applications: It can be used to treat various industrial organic wastewaters containing high COD or compounds that cannot be degraded by biological methods (such as ammonia nitrogen, polycyclic aromatic hydrocarbons, etc.).

(4) Operating Cost Analysis

When calculating the operating cost of catalytic wet oxidation, we considered the following assumptions: The raw water COD is tentatively set at 40000mg/L, the required oxygen concentration is 90%, the catalyst (homogeneous) addition amount is 0.1%, copper-based inorganic salts are used, and when the oxidation process is stably operating, the heat released by the reaction can heat the preheated wastewater to the required temperature. The small table shows the energy consumption analysis of the CWAO operation process using homogeneous catalysts, and the calculation process is the cost required for treating each cubic meter of wastewater.

CWAO operating energy consumption analysis

|

Project |

Specific consumption |

Unit price |

Cost, yuan/m 3 Wastewater |

|

Catalyst (homogeneous) |

1kg / m 3 Wastewater |

10000~15000 yuan/ton |

10~15 |

|

Power consumption of transfer pump |

3~3.5 kw/m 3 Wastewater |

1 yuan/kwh |

3~3.5 |

|

Oxygen |

68 Nm3/m3 Wastewater |

0.45~0.5 kw/Nm 3 |

31~34 |

|

Total |

/ |

/ |

44~53 |

(5) Application Fields

Suitable for treating industrial wastewater with high COD or compounds that cannot be degraded by biological methods from coking, dyeing, pesticide, printing and dyeing, petrochemical, and leather industries.

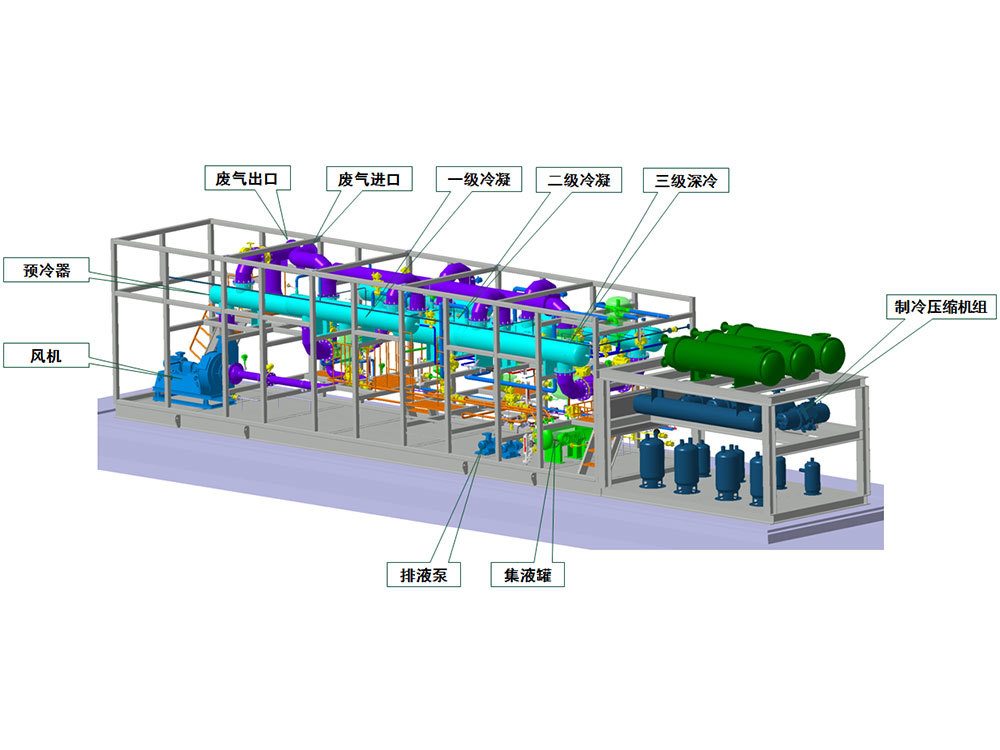

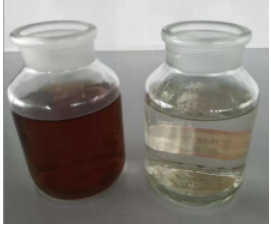

(6) Engineering Pictures

Effluent effect of chemical wastewater Effluent effect of pharmaceutical wastewater

Keywords:

Wastewater treatment