Product series

Contact us

Phone: +86-5065741650

Manager Wang

Email: 15065709046@163.com

Address: No. 10, District 1, 300 Changjiang Road, Yantai Economic and Technological Development Zone

Industrial Powder Drying

A technology-based enterprise focusing on industrial gas separation and purification with gas separation membrane as the core technology

- Commodity name: Industrial Powder Drying

Product details

Equipment Introduction

A powder heat pump dryer is a continuous material drying equipment that utilizes heat pump technology. It combines mesh belt conveying and heat pump technology to achieve an efficient, uniform, energy-saving, and environmentally friendly drying process for materials. This equipment is widely used in industries such as food, chemical, and pharmaceutical for drying powdered, granular, and flaky materials.

Main Features

● Low moisture content: The final product after dehydration has a moisture content of ≤1%;

● High efficiency and energy saving: Heat pump technology achieves high efficiency and energy saving through energy recovery and recycling. Compared with traditional drying equipment, the energy consumption of heat pump mesh belt drying equipment can be reduced by more than 30%, and the heat utilization rate can reach over 80%.

● Uniform drying: Layered mesh belts are used to transport materials, allowing them to be heated uniformly during the drying process, avoiding problems such as material accumulation and uneven drying found in traditional drying equipment. At the same time, by adjusting the mesh belt speed and hot air temperature, precise control over the material's drying degree can be achieved. The layered mesh belt drying area is several times that of conventional models, offering advantages such as thin material spreading, low wind speed, and long drying time.

● Easy to operate: The equipment adopts an intelligent control system, realizing automation and visualization of the drying process. Users can easily set drying parameters via the touch screen and monitor the drying process in real time. In addition, the equipment also has self-diagnosis and alarm functions, making it convenient for users to discover and solve problems promptly.

● Environmentally friendly and safe: Heat pump mesh belt drying equipment has no combustion process, reducing exhaust gas emissions and noise pollution. At the same time, the equipment uses high-quality materials and manufacturing processes, ensuring its stability and safety.

● Service life: 90% of the machine's material is 304 stainless steel, and equipment parts adopt a modular design, facilitating future maintenance.

● Energy consumption: The heat source uses heat pump clean energy, which is safe and reliable, consuming 150-300 kWh/ton of water.

● Smart operation: Automatic feeding and discharging, fully automatic operation, closed drying, reducing labor costs.

Working Principle

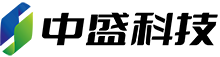

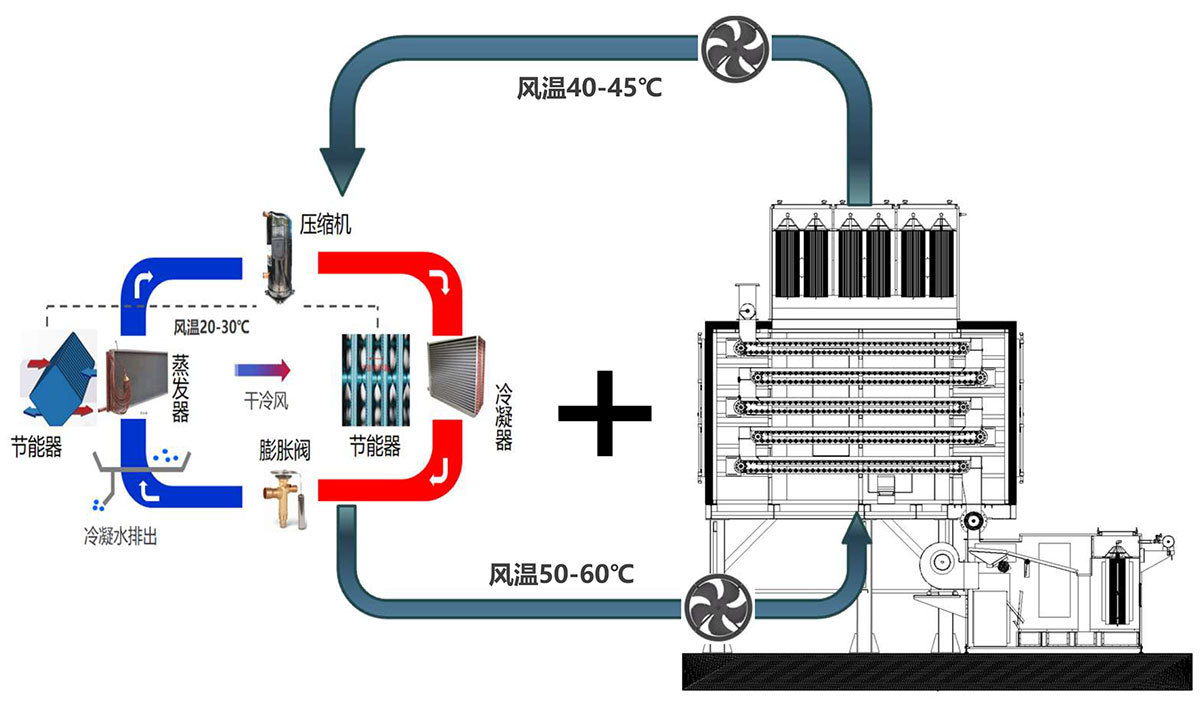

Heat Pump Drying Process

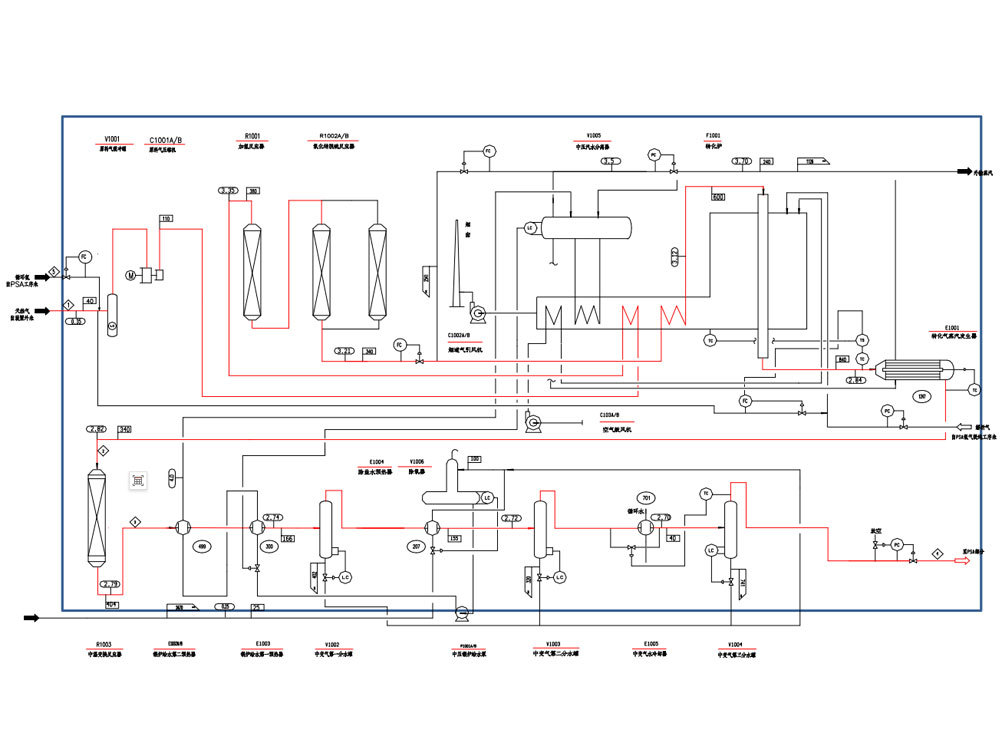

● The heat pump mesh belt drying equipment mainly consists of a heat pump system, a mesh belt conveying system, a hot air closed-loop circulation system, and a control system. The heat pump system generates heat through refrigerant circulation, transferring this heat to the air to form hot air. The hot air enters the drying chamber through the air supply system to dry the materials on the mesh belt. Materials continuously advance on the mesh belt, undergoing multi-layer drying. Simultaneously, the dehumidification system discharges moisture from the drying chamber, while the heat from the moisture is reused through the recovery system. The hot air closed-loop circulation system ensures the recycling of hot air within the drying chamber, improving heat energy utilization. The control system automatically adjusts the operating status of the heat pump system, air supply system, and dehumidification system according to user-set drying parameters, ensuring the stability and efficiency of the drying process.

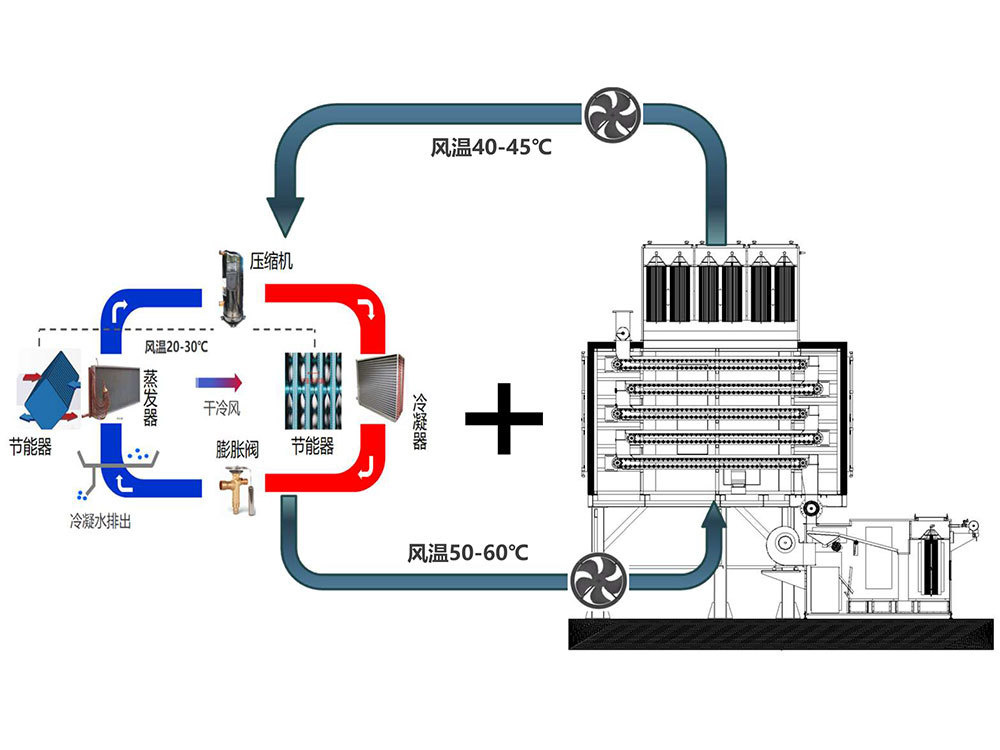

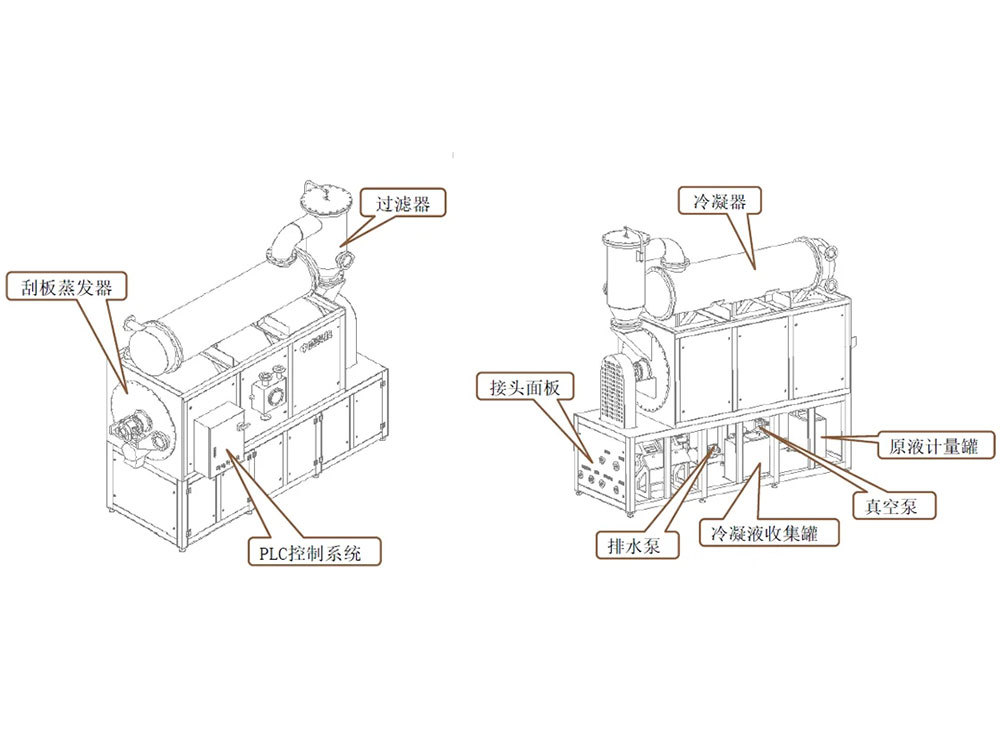

Structure Composition

Advantages

● 1. Volume reduction: Can evaporate materials to a moisture content of approximately ≤1%;

● 2. Energy saving: Heat pump technology enables energy recovery and utilization, reducing energy consumption;

● 3. Environmental protection: Enclosed drying, reducing exhaust emissions and pollution;

● 4. Safe and reliable: Industrial design, modular assembly leads to low equipment failure rates;

● 5. Easy to operate: Intelligent control system, realizing automation and visualization of the drying process;

● 6. High efficiency: Layered evaporation method, larger drying area, higher drying efficiency;

● 7. Smart: Automatic dust removal, automatic tailing screening

Application Areas

Keywords:

Industrial Powder Drying