Product series

Contact us

Phone: +86-5065741650

Manager Wang

Email: 15065709046@163.com

Address: No. 10, District 1, 300 Changjiang Road, Yantai Economic and Technological Development Zone

Low temperature evaporation scraper

A technology-based enterprise focusing on industrial gas separation and purification with gas separation membrane as the core technology

- Commodity name: Low temperature evaporation scraper

Product details

The low-temperature evaporative scraper is a new type of evaporation equipment suitable for various low-temperature evaporation processes. It features high efficiency, energy saving, and environmental protection, and is widely used in the chemical, pharmaceutical, and food industries.

Main Features

• After dehydration of waste liquid, the final product contains ≤10% water content in particles or colloids;

• Approximately 40℃ low-temperature vacuum drying, using steam as thermal energy to separate water and waste from the waste liquid, condensing and discharging distilled water, COD can be reduced by 99%, achieving up-to-standard discharge or reuse of recycled water.

• During the evaporation process, the built-in scraper continuously reciprocates and stirs the waste liquid, preventing crystallization on the cylinder wall and enabling more effective heat transfer between the waste liquid and the heat source. After drying, the scraper spirals to discharge the waste.

• Materials in contact with waste liquid use stainless steel materials such as SUS316L\2205\2507 or titanium materials. Equipment components use an assembly design for easy maintenance.

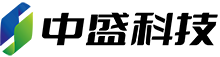

• The heat source uses clean energy such as steam or heat pumps, which is safe and reliable. (Steam type) 1.2 tons of steam/ton of water, (heat pump type) 233 kw.h/ton of water.

• Touch screen and PLC automatic control, low failure rate, simple and practical operation.

• Waste liquid inlet, evaporation, condensation, distilled water, waste discharge, fully automatic operation, closed drying, reducing waste gas emissions, and reducing pollution.

• The entire machine is modular in design and can be assembled in multiple modules according to the processing capacity, making installation convenient and reducing the footprint.

Low-Temperature Evaporation Equipment Data Table

|

Daily Processing Capacity (tons/day) |

Evaporation Capacity (liters/hour) |

Energy Consumption per Ton of Water (tons of steam, power consumption kw.h) |

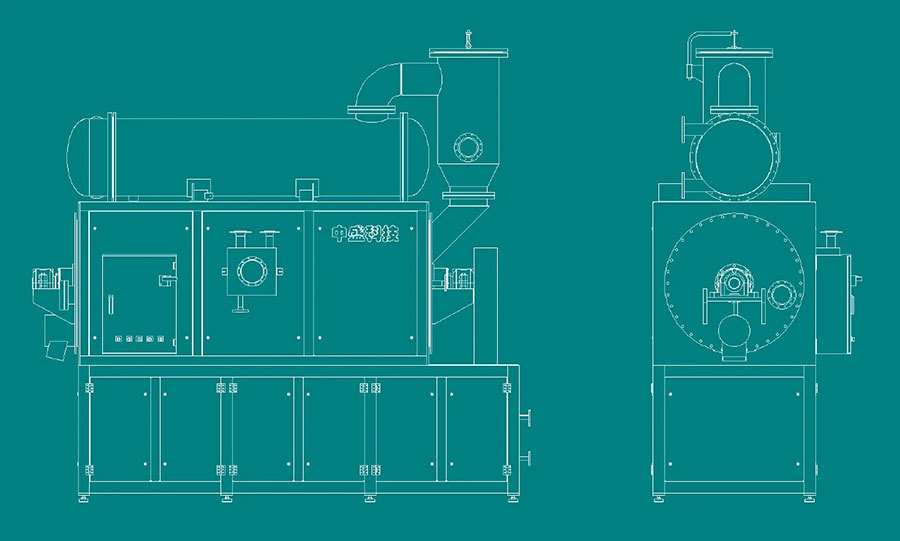

Equipment Dimensions (length × width × height, meters) |

Equipment Weight (tons/unit) |

|

5 |

208 |

1.2 tons of steam, 25 kw.h |

3.8 × 1.4 × 3.9 |

8.6 |

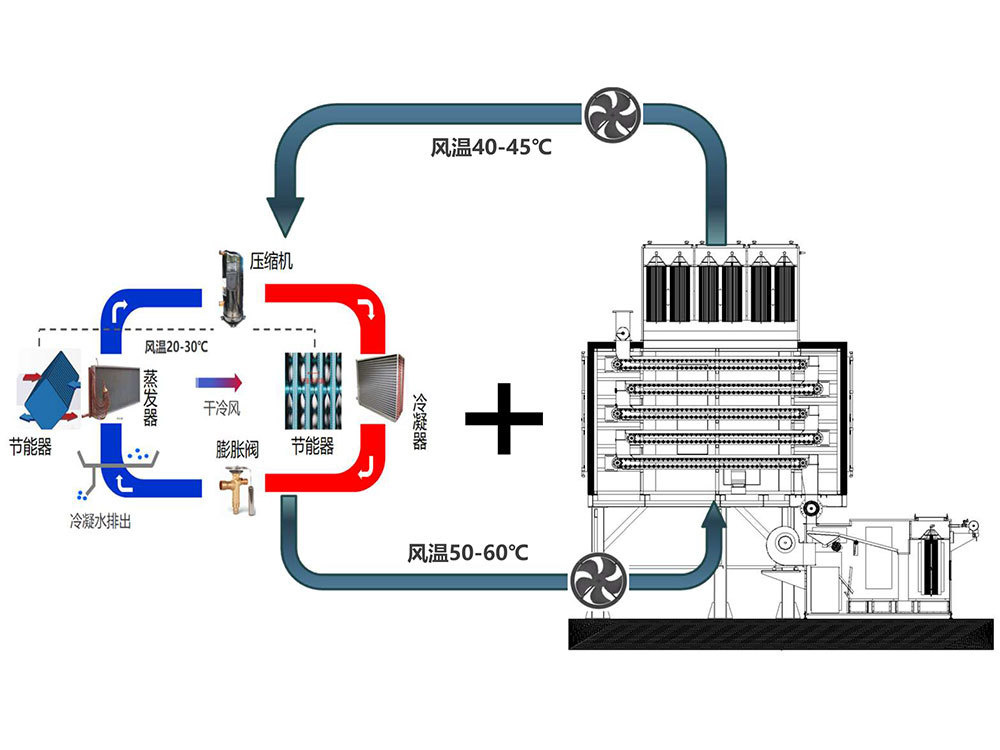

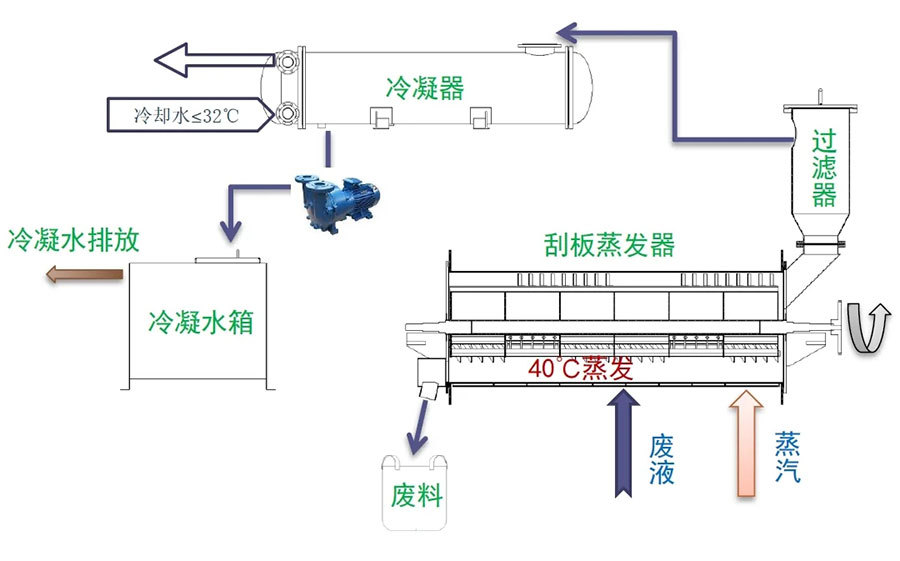

Working Principle (Scraper Evaporation Process)

1. Waste liquid is pumped into the metering tank and then vacuumed into the scraper evaporator.

2. The vacuum pump evacuates the entire system to -80~-90kpa, and the waste liquid is heated to about 40℃ for boiling and evaporation. Low temperature prevents secondary changes in the raw materials.

3. During the heating process, the scraper reciprocates and stirs to ensure uniform heating of the solution. The evaporation cycle can be set, and slag is automatically discharged at the end.

4. The evaporated distilled water is cooled and condensed to the water tank by industrial cooling water and discharged or reused via a pump.

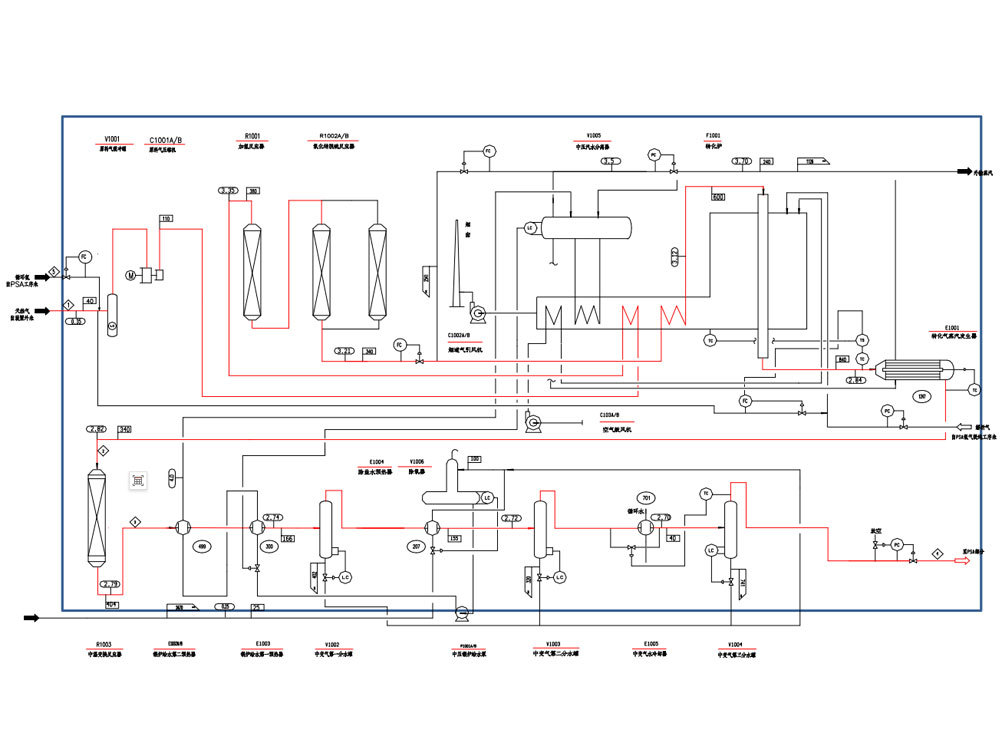

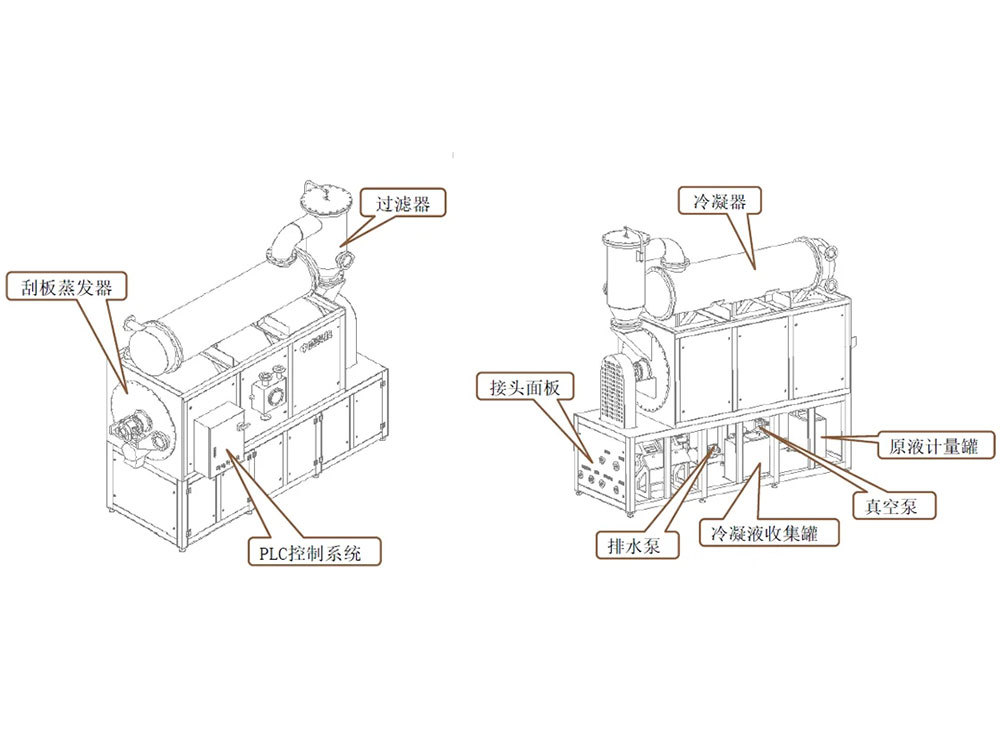

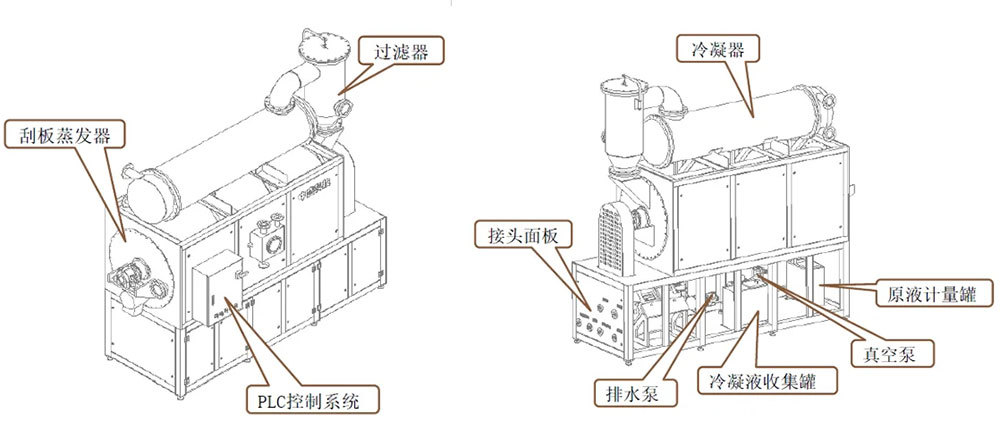

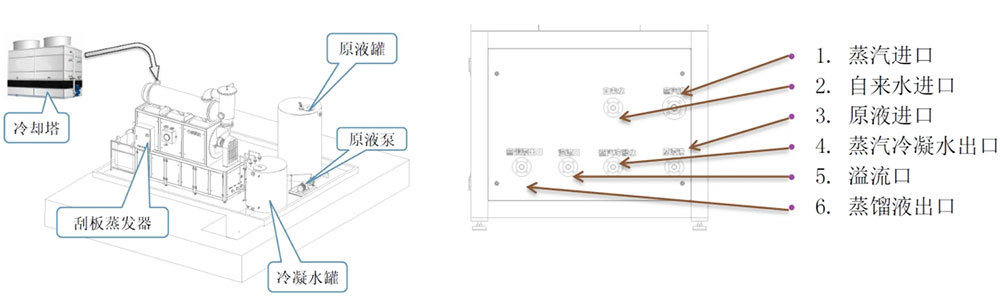

Structural Composition

1. Scraper evaporator 2. Filter 3. Condenser 4. Condensate collection tank 5. Raw material metering tank 6. Vacuum pump 7. Drainage pump 8. PLC control system 9. Connector panel

Matching Equipment

Application Areas

Providing you with a one-stop solution

Conclusion

As a highly efficient, energy-saving, and environmentally friendly evaporation equipment, the low-temperature evaporative scraper will play an increasingly important role in industrial production. Let us work together to achieve "zero discharge" of industrial wastewater.

Keywords:

Low temperature evaporation scraper