Product series

Contact us

Phone: +86-5065741650

Manager Wang

Email: 15065709046@163.com

Address: No. 10, District 1, 300 Changjiang Road, Yantai Economic and Technological Development Zone

VOC cryogenic recovery equipment

A technology-based enterprise focusing on industrial gas separation and purification with gas separation membrane as the core technology

- Commodity name: VOC cryogenic recovery equipment

Product details

Industry Pain Points and Solutions

Frosting and Shutdown Issues Due to High-Humidity Waste Gas

High-humidity waste gas is prone to frosting at low temperatures, blocking heat exchangers, leading to equipment shutdown and production losses of up to 15%.

Traditional equipment lacks effective preventive measures, and companies often miss production peaks due to equipment downtime.

Challenges in Capturing Low-Boiling-Point VOCs

Traditional cryogenic equipment struggles to effectively capture low-boiling-point VOCs such as ethylene, resulting in exceeding emission standards and facing environmental penalties.

A chemical company was fined for exceeding emission standards of low-boiling-point VOCs, impacting its reputation.

High Electricity Costs of Traditional Cryogenic Equipment

Traditional cryogenic equipment has high pre-cooling energy consumption, consuming 120 kW per hour and resulting in annual electricity costs of up to one million, making costs uncontrollable.

For a certain company, due to excessively high electricity costs, equipment operating costs account for 30% of the total cost, severely squeezing profits.

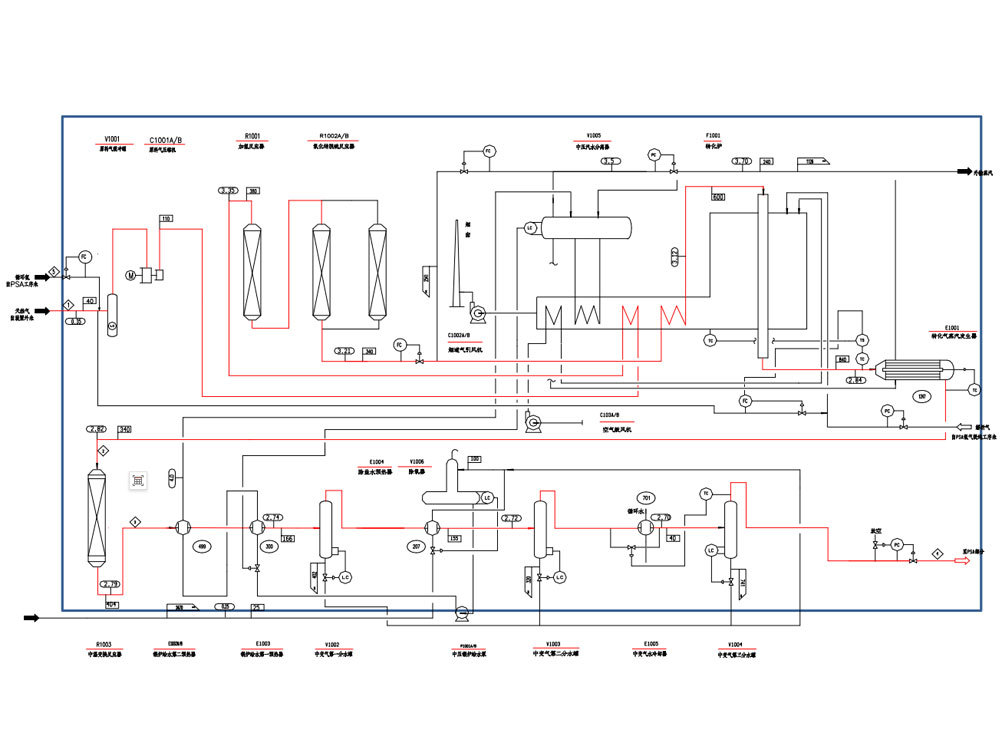

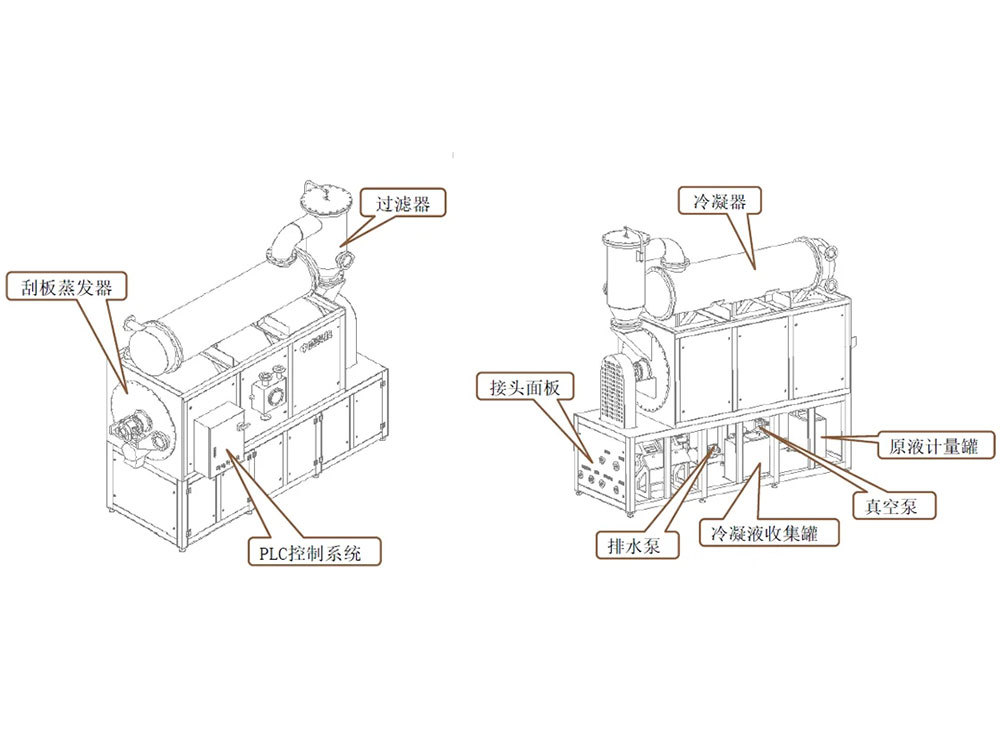

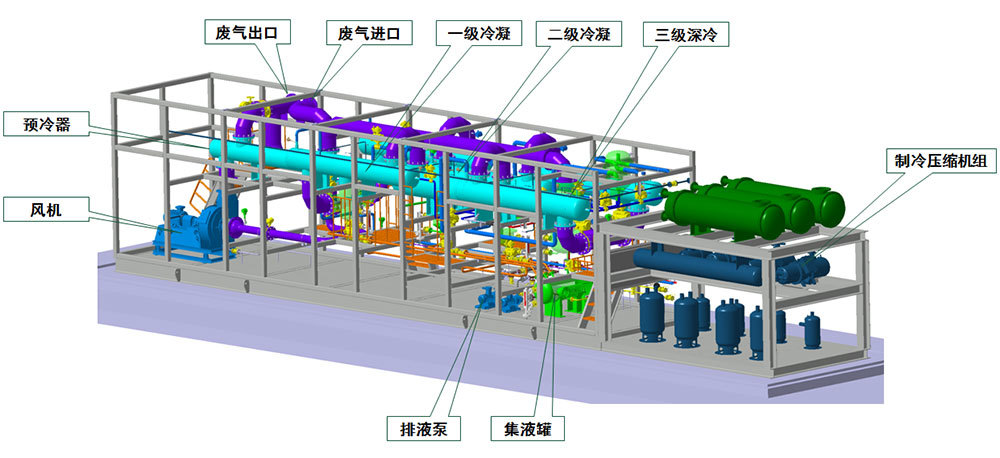

3D Design Drawing of VOCs Cryogenic Recovery Equipment

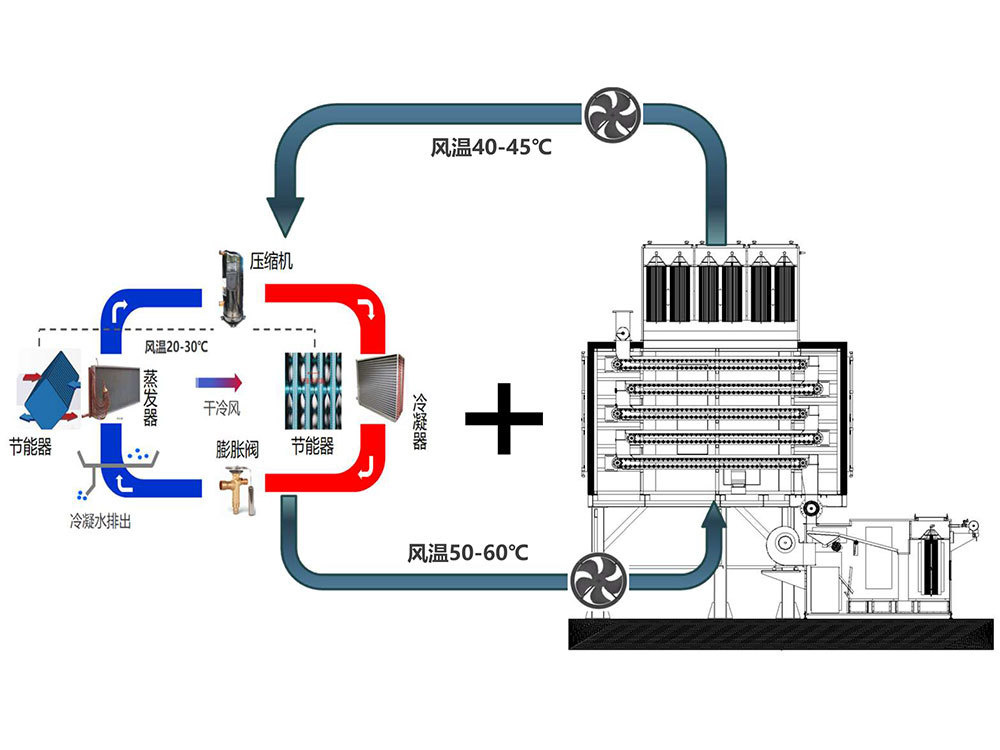

Process Design of VOCs Cryogenic Recovery Equipment

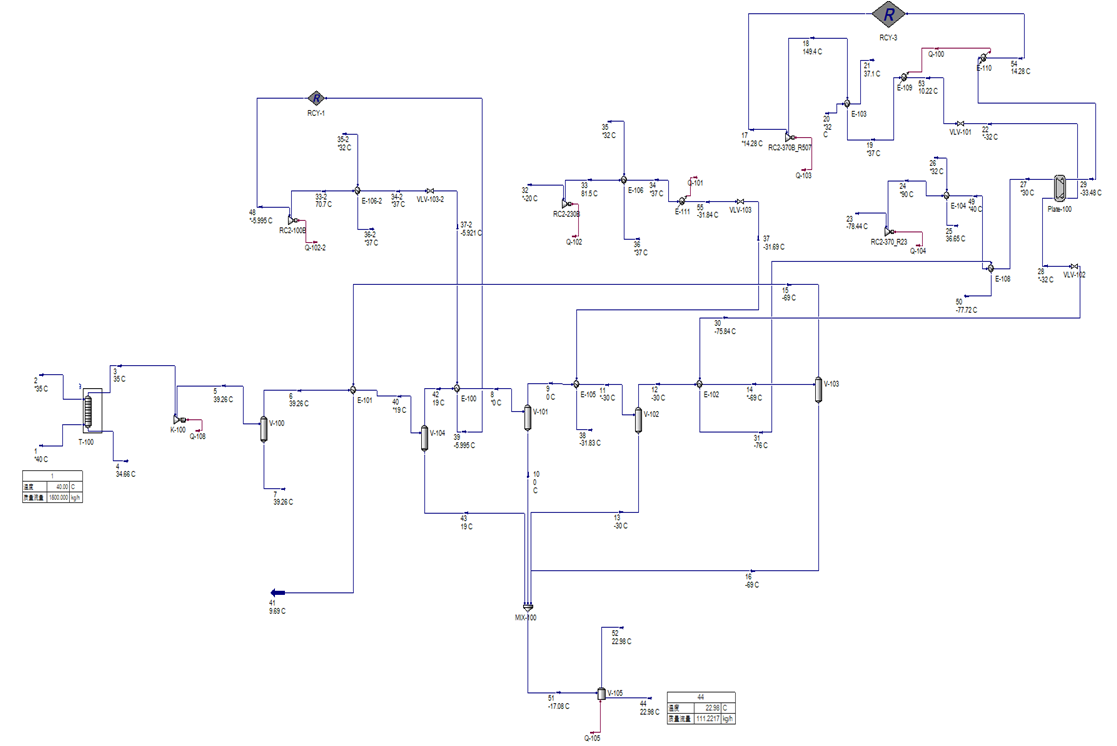

ASPEN Process Simulation

Process Flow:

Waste Heat Pre-cooling (Zero Energy Consumption)

Principle: Utilizing the -70℃ ultra-low temperature waste gas generated by the equipment itself, through a shell-and-tube heat exchanger with high-temperature original waste gas (40℃) for counter-current heat exchange.

Effect: The original waste gas temperature is reduced from 40℃ to 10-20℃, without any external energy input throughout the process, achieving 100% energy saving.

Three-Stage Cascade Refrigeration

First Stage (0℃): Preliminary condensation of high-boiling-point VOCs (such as benzene, toluene), without defrosting design, reducing subsequent load;

Second Stage (-30℃): Medium and low-temperature condensation of medium-boiling-point components (such as ethyl acetate), integrated with automatic defrosting function;

Third Stage (-70℃): Ultra-low temperature deep capture of low-boiling-point VOCs (such as ethylene, chloromethane), with efficient refrigerant (R23) circulation.

Dual-Channel Intelligent Switching

Operating Mode: A/B channels operate independently. When frosting is detected, or according to the time sequence, the channels are switched to ensure 24-hour continuous processing.

Condensation and Recovery

Liquid VOCs are automatically recovered through a collection tank, with a purity >99%, and can be directly reused in production; uncondensed gases enter the next stage.

Emission Compliance

After deep cooling, the tail gas is sent to the adsorption system for safe and compliant emission.

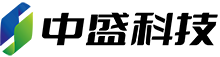

Cold Energy Self-Circulation System

Principle of Zero-Energy Consumption Pre-cooling Technology

★ Waste Cold Recovery After Three-Stage Refrigeration

The -70℃ waste gas after three-stage refrigeration enters a high-efficiency heat exchanger, utilizing the waste cold to pre-cool the original 40℃ waste gas, achieving cold energy recycling. Through waste cold recovery, pre-cooling energy consumption is reduced to 0kW.

★ High-Efficiency Energy Saving Through Counter-Current Heat Exchange

The original 40℃ waste gas and -70℃ waste gas use a new type of high-efficiency heat exchanger for counter-current heat exchange, pre-cooling to 10-20℃, without external energy input, significantly improving energy saving.

The counter-current heat exchange efficiency is 30% higher than traditional co-current heat exchange, and the pressure vessel manufacturing standard makes the equipment operation more stable and extends its service life.

★ Pre-cooling Energy Consumption Comparison

Traditional pre-cooling methods have high annual electricity consumption; this equipment has zero pre-cooling energy consumption.

Based on a processing capacity of 5000m³ and 300 days of annual operation, traditional equipment consumes 360,000 kWh, with electricity costs of approximately 300,000 yuan, while this equipment requires no electricity costs.

Dual-Channel Continuous Operation Guarantee

Dual-Channel Intelligent Switching System

A/B Channel Independent Operation Logic ▶

A/B channels operate independently without affecting each other. When one channel is operating, the other channel is on standby, ensuring continuous operation of the equipment.

During equipment operation, channel A processes waste gas, and channel B is on standby. Once channel A encounters a problem, channel B immediately switches over seamlessly.

Automatic Switching Logic ▶

After a frosting warning in channel A, the system automatically switches to channel B within 5 seconds, with a smooth switching process that does not affect production.

Customer Value and Cost Savings ▶

Production loss is reduced to <1%, compared to 15% for traditional equipment; maintenance labor costs are reduced by 40%, reducing the burden on enterprise operations.

After using this equipment, a certain company recovered over 2.6 million yuan annually, demonstrating significant economic benefits.

Economic Benefits

Investment Return Model Analysis

Taking a processing capacity of 2000m³/h as an example, the equipment investment is 3.5 million yuan, and the solvent recovery value is 2.6 million yuan.

The payback period is only 1.35 years, with a return on investment of 74%, and considerable long-term returns.

Long-Term Revenue Generation and Sustainable Development

The equipment operates stably, with high solvent recovery value, generating long-term revenue for the enterprise;

It complies with environmental protection policies, helping enterprises achieve sustainable development.

Industry Benchmark Case

A chemical company with a processing capacity of 2000m³/h and a solvent recovery of 2.4m³/day.

Keywords:

VOC cryogenic recovery equipment