Product series

Contact us

Phone: +86-5065741650

Manager Wang

Email: 15065709046@163.com

Address: No. 10, District 1, 300 Changjiang Road, Yantai Economic and Technological Development Zone

Natural gas reforming hydrogen production technology

A technology-based enterprise focusing on industrial gas separation and purification with gas separation membrane as the core technology

- Commodity name: Natural gas reforming hydrogen production technology

Product details

Key Points and Characteristics of Process Flow Design

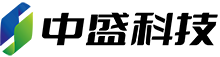

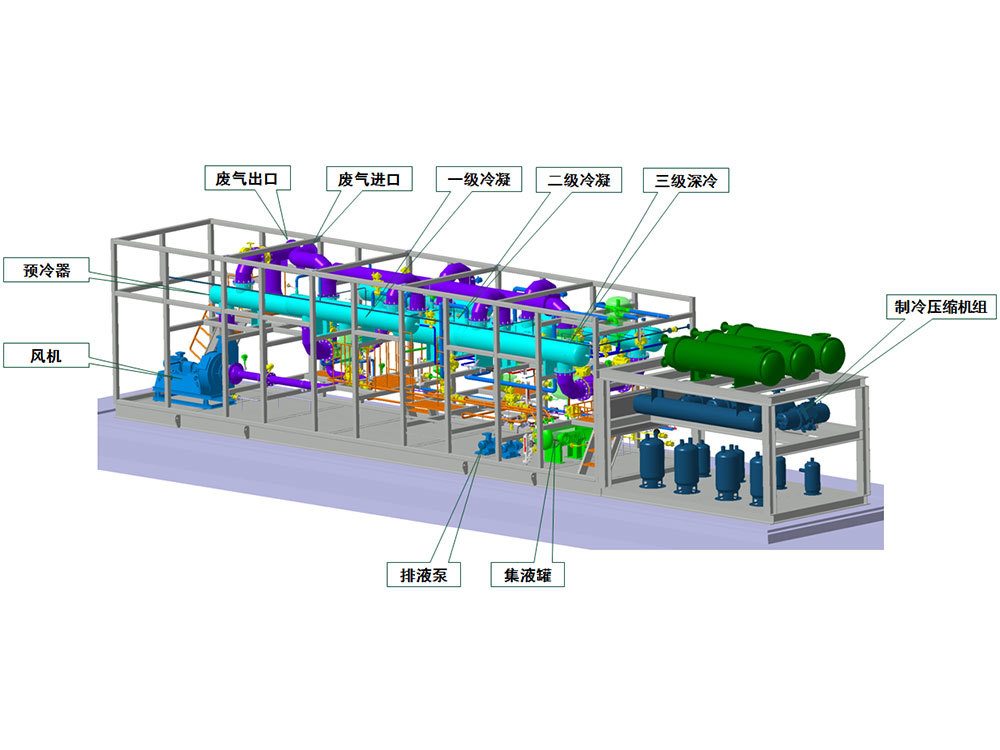

Waste Heat Recovery Process Design of the Device

A. Waste heat recovery of the converter: exhaust gas temperature 160-170 degrees; efficiency>90% Preheating air scheme is adopted, so the exhaust gas temperature is reduced

B. Waste heat recovery of converted gas

C. Waste heat recovery of intermediate converted gas

Steam system design:

A. Steam can be generated according to user requirements

B. No external steam supply is required for start-up

Utilization of PSA-resolved gas (using patented burner)

Direct combustion at 0.03MPa.G, low energy consumption, high PSA yield

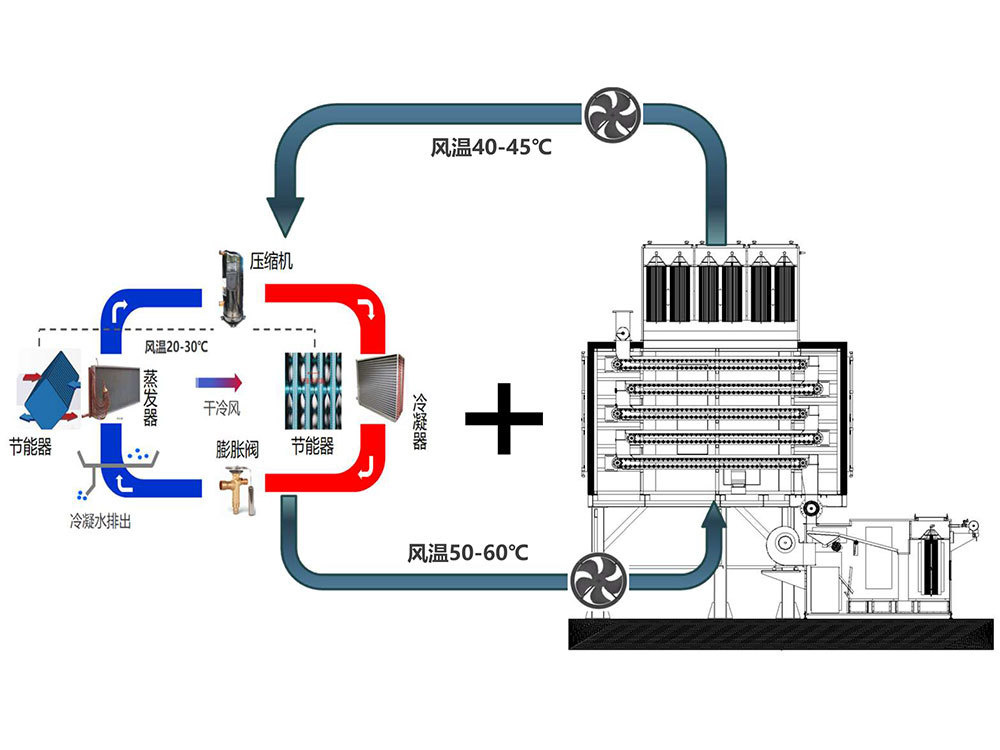

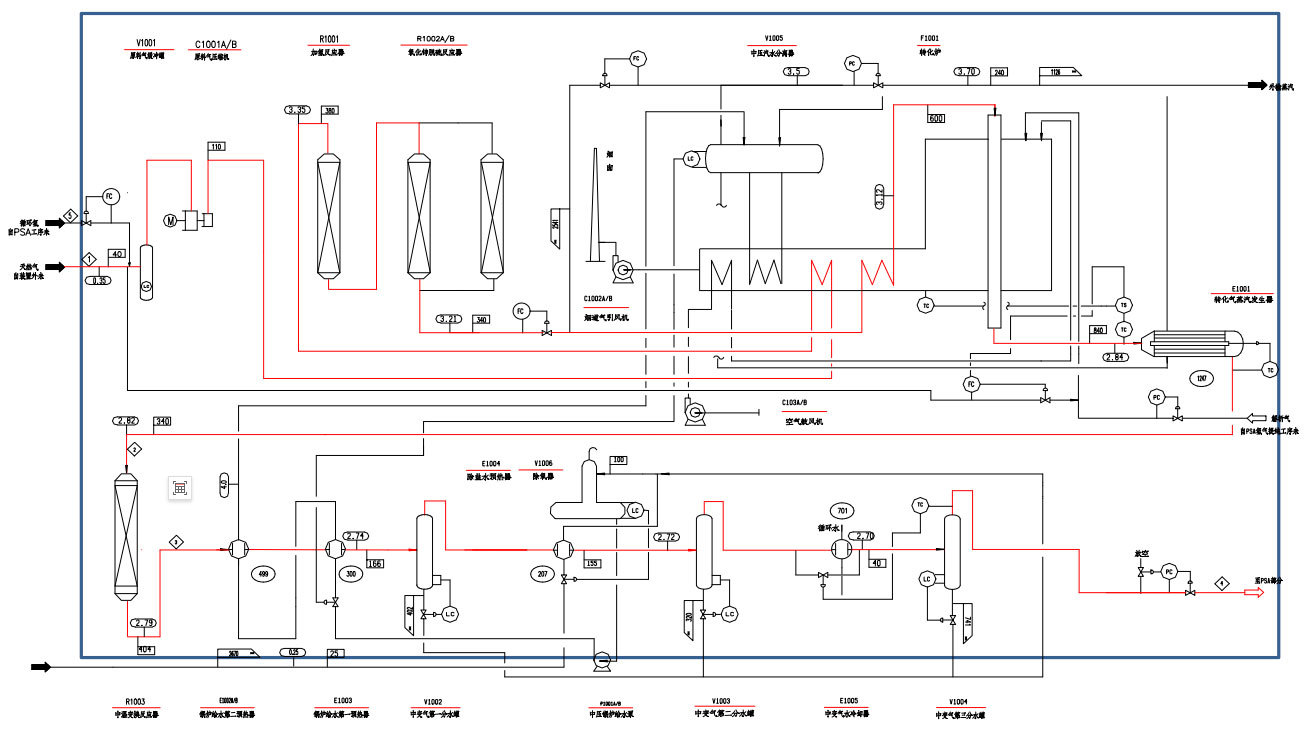

Process flow diagram of gas generation part of hydrogen production unit

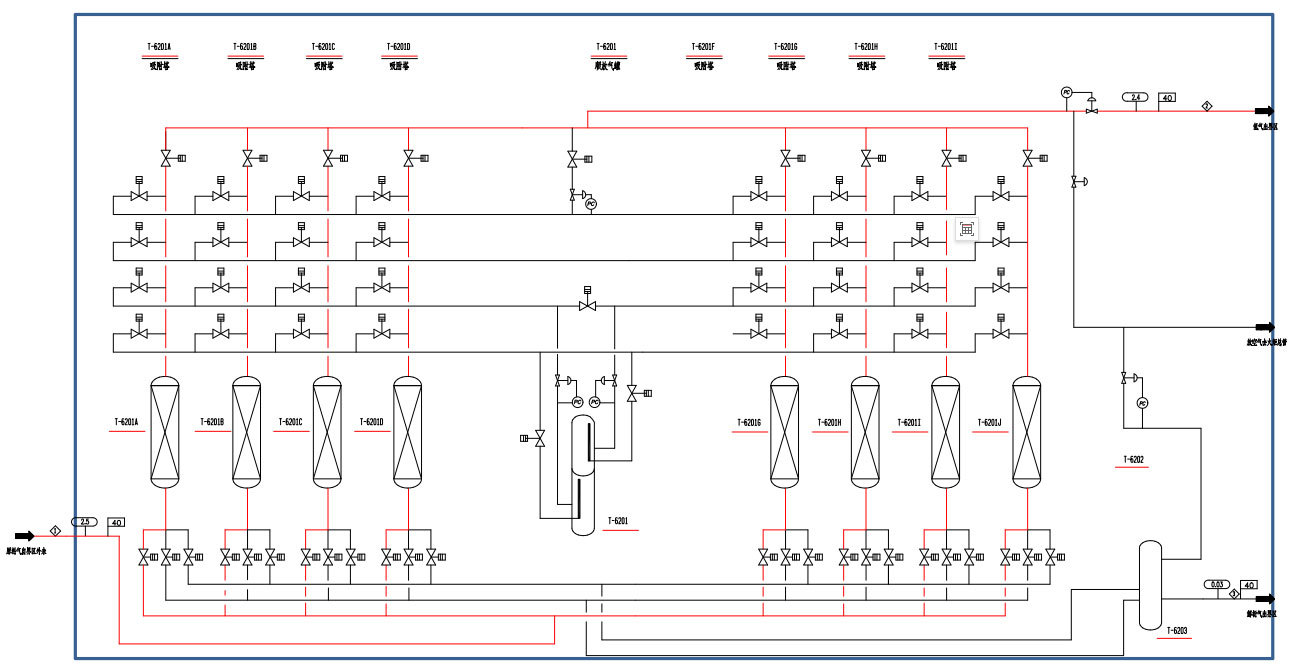

Process flow diagram of PSA part of hydrogen production unit

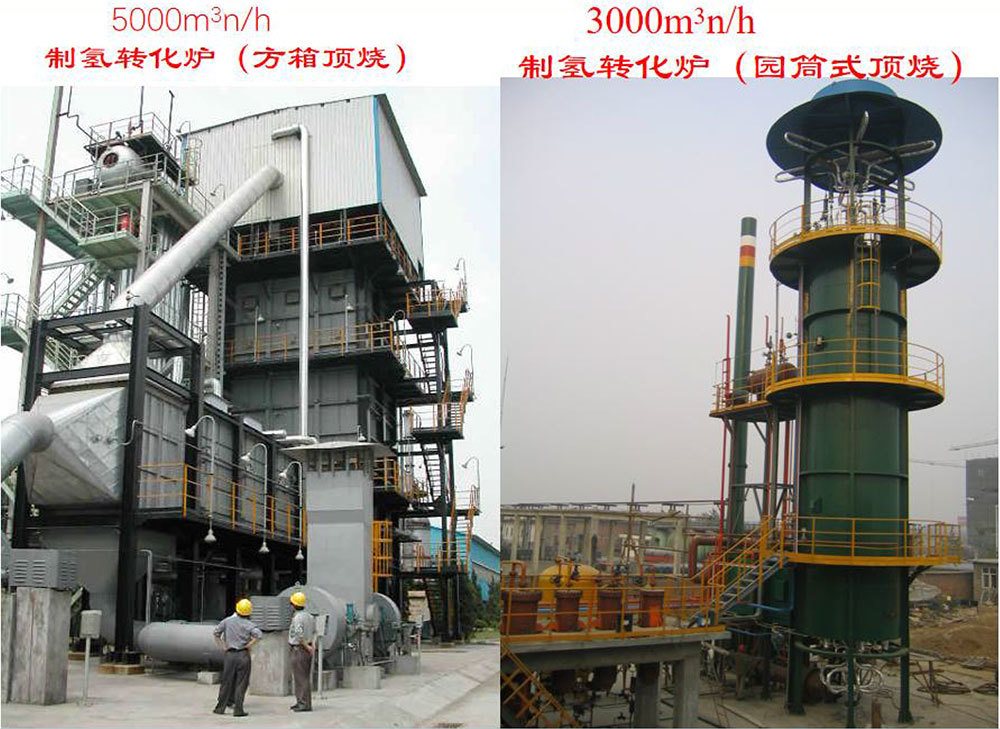

Application Cases

2000Nm3 Summary table of consumption of /h natural gas hydrogen production unit

|

Serial Number |

Name |

Unit |

Quantity |

Remarks |

|

1 |

Raw material gas |

Nm³ 3/h |

710 |

Continuous (natural gas) |

|

2 |

Fuel gas |

Nm³ 3/h |

160 |

Continuous (natural gas) |

|

3 |

Circulating water |

t/h |

69 |

Continuous |

|

|

|

t/h |

10 |

Intermittent |

|

4 |

Domestic water |

t/h |

1 |

Intermittent |

|

5 |

Demineralized water |

t/h |

2.3 |

Continuous |

|

6 |

Electricity 380V |

KWh/h |

73 |

Continuous (raw material gas compression) |

|

|

220V |

KWh/h |

22 |

Continuous (machinery and pumps) |

|

7 |

Purified compressed air |

m³ 3n/h |

100 |

Continuous |

|

8 |

1.0MPa steam |

t/h |

-1.2 |

External delivery |

|

|

1.0MPa steam |

t/h |

2 |

Fire fighting and purging |

|

9 |

Nitrogen |

m³ 3n/h |

200 |

Intermittent |

Keywords:

Natural gas reforming hydrogen production technology