Product series

Contact us

Phone: +86-5065741650

Manager Wang

Email: 15065709046@163.com

Address: No. 10, District 1, 300 Changjiang Road, Yantai Economic and Technological Development Zone

Helium recovery system

A technology-based enterprise focusing on industrial gas separation and purification with gas separation membrane as the core technology

- Commodity name: Helium recovery system

Product details

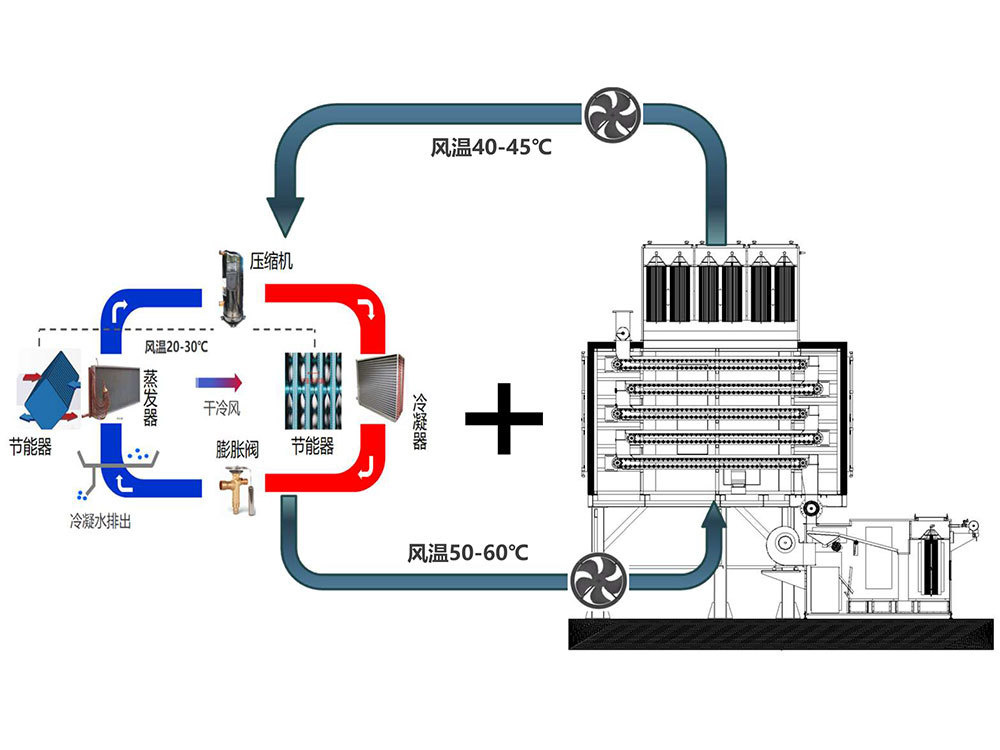

(1) Technical Introduction

Helium recovery in helium leak detection mainly consists of three parts: a, evacuation; b, helium charging; c, recovery.

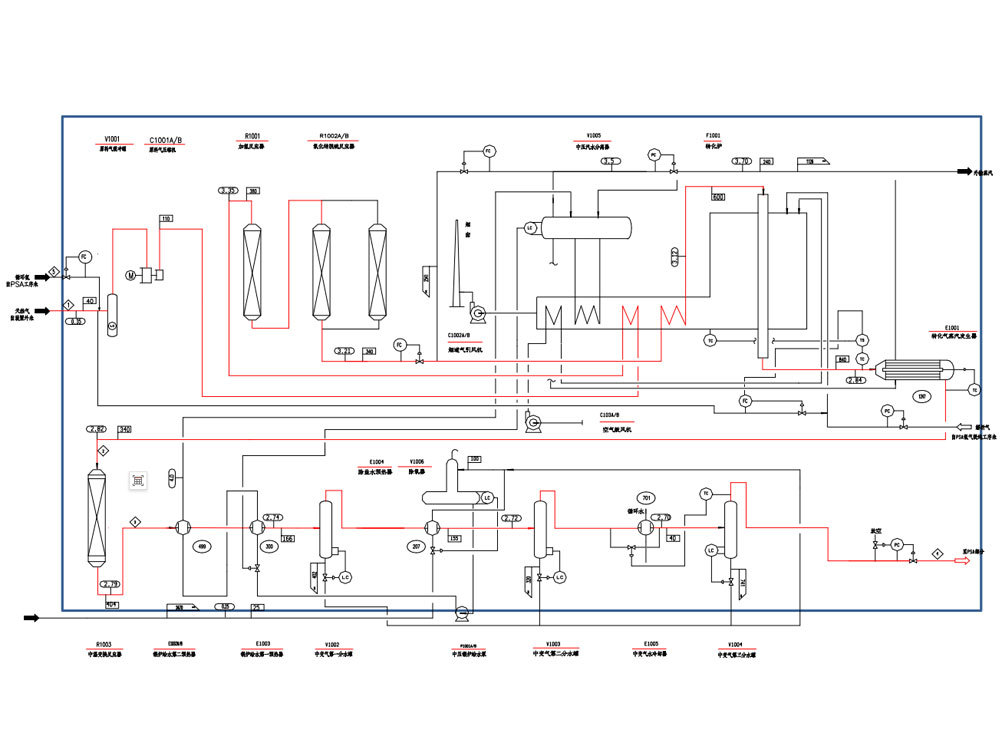

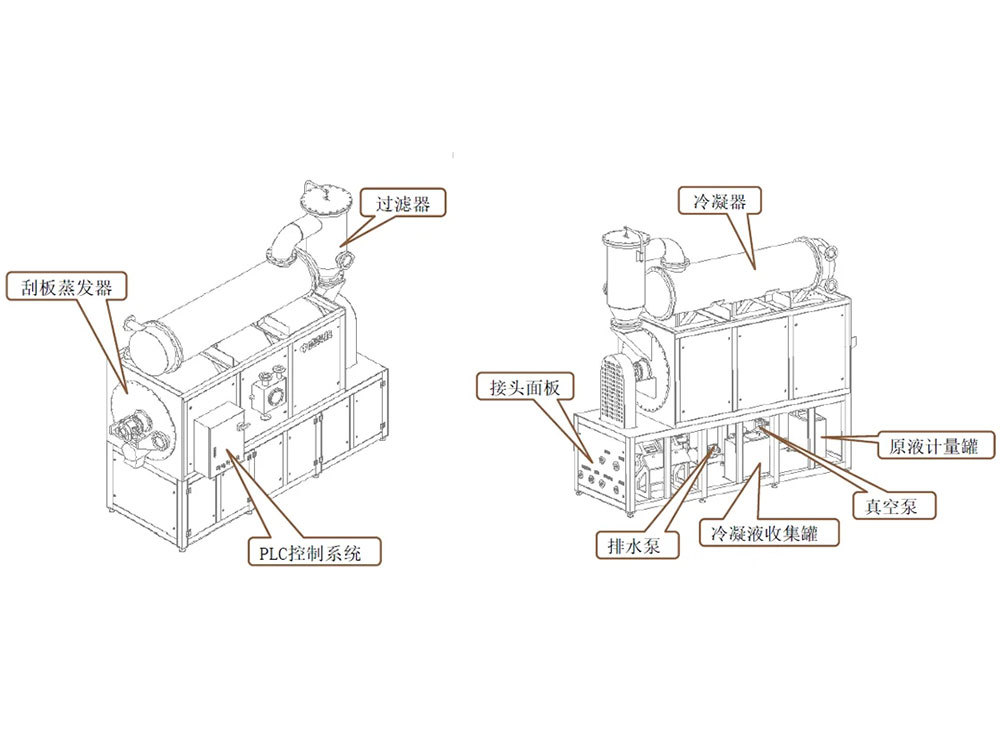

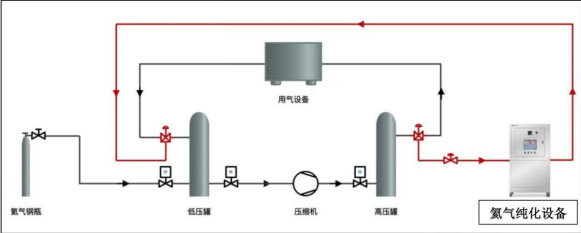

The process flow of recovery membrane separation is very simple and can be divided into two parts: pretreatment and membrane separation.

The pretreatment system consists of a high and low-pressure tank gas supply system. Cylinder helium passes through the low-pressure tank and then through the compressor to the high-pressure tank. When the pressure in the high-pressure tank reaches the set value, the cylinder helium is closed. The production line uses helium for leak detection. After helium detection, the helium is recovered into the low-pressure tank, then compressed into the high-pressure tank for continued use, and so on. When the helium concentration in the high-pressure tank drops to a specified value (90%), the helium purification equipment connects the high-pressure tank and the low-pressure tank through a bypass, and the helium flows as shown by the red arrow, entering the purification equipment from the high-pressure tank and then flowing back to the low-pressure tank. By controlling the valves inside the purification equipment and adjusting the flow rate, the concentration of the high and low-pressure tanks is maintained above the alarm line without affecting the normal continuous operation of the helium detection equipment, avoiding exhaust and thus improving the utilization rate of helium. (For example, the working concentration of the high-pressure tank is currently 86%, part of the gas enters the purification equipment through the pipeline, and the helium concentration coming out of the purification equipment is 99%, which is transported back to the low-pressure tank and then pumped into the high-pressure tank by the compressor, so that the helium concentration in the high-pressure tank can be increased). When the pressure in the high-pressure tank is insufficient, helium needs to be replenished from the cylinder to maintain the pressure.

(2) Process Flow

(3) Technical Features

A. Using a low-pressure tank to replenish helium can utilize cylinder helium to one atmospheric pressure, greatly improving helium utilization;

B. Through the reasonable configuration of the high-pressure tank, low-pressure tank, and compressor, the compressor works intermittently, ensuring the service life of the compressor;

C. Automatically monitor the pressure or concentration in the gas storage tank (high-pressure tank). When it is lower than the specified value, it automatically prompts and automatically replenishes pure helium to maintain sufficient pressure and concentration of helium in the gas storage tank.

D. Using non-standard customized compressors and improving the sealing mechanism greatly increases the sealing performance of the compressor, reducing helium waste.

(4) Application Fields

Hydrogen-powered vehicle cylinder testing, new energy battery testing, semiconductor product testing

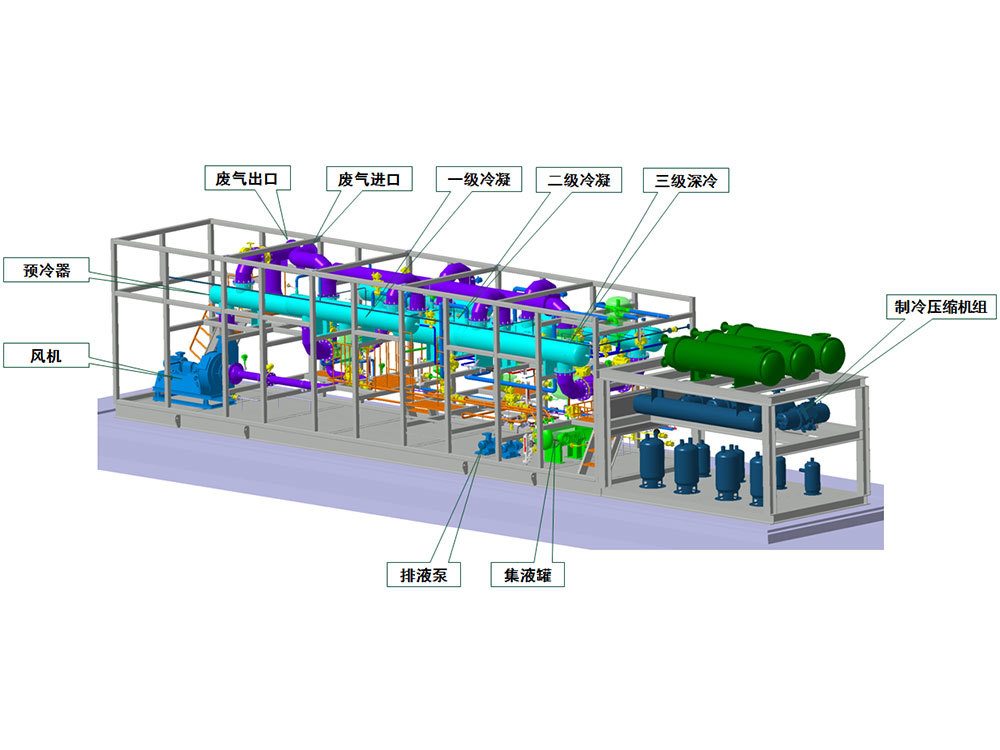

(5) Engineering Pictures

Keywords:

Helium recovery system