Product series

Contact us

Phone: +86-5065741650

Manager Wang

Email: 15065709046@163.com

Address: No. 10, District 1, 300 Changjiang Road, Yantai Economic and Technological Development Zone

VOC gas separation membrane

A technology-based enterprise focusing on industrial gas separation and purification with gas separation membrane as the core technology

- Commodity name: VOC gas separation membrane

Product details

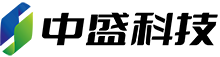

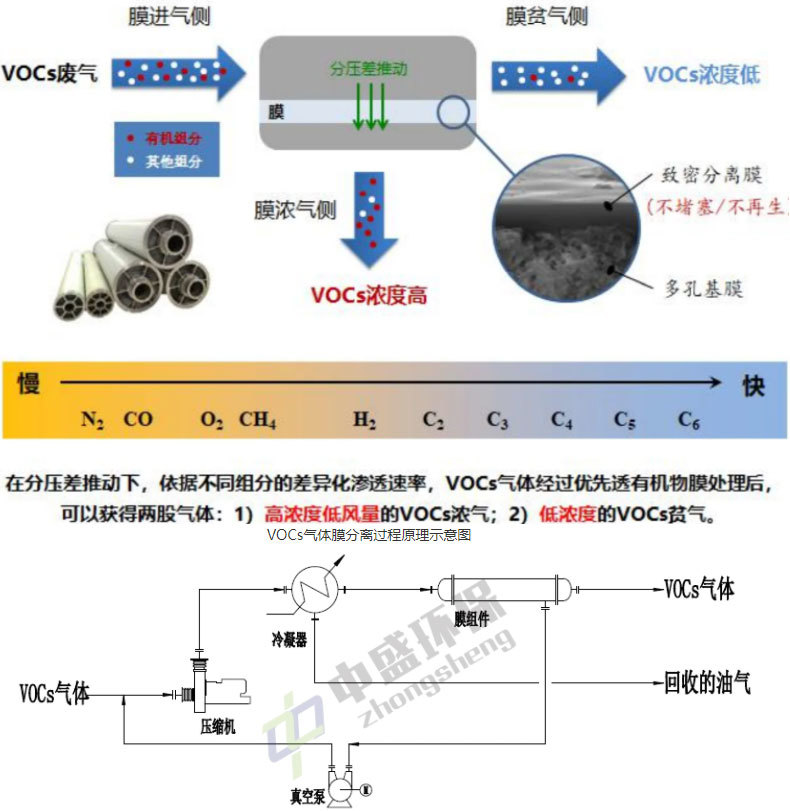

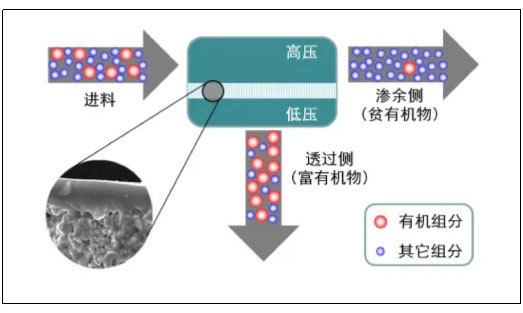

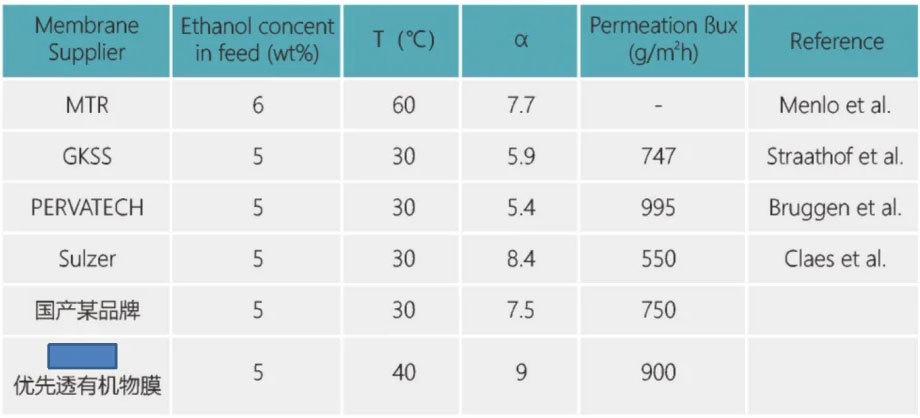

Membrane separation utilizes the difference in permeation rates of organic hydrocarbons and inert components in a polymer membrane to achieve the separation of their mixture. Driven by a certain pressure difference, VOCs molecules preferentially permeate the polymer membrane, while inert components such as air are retained and discharged, ultimately achieving the concentration and enrichment of organic hydrocarbons. After heat exchange of the uncondensed gas, it enters the membrane unit. Utilizing the fact that the dissolution and diffusion rate of VOCs components in the membrane material is greater than that of air or nitrogen, the pressure difference between the upstream and downstream of the membrane system allows for the enrichment of VOCs components on the downstream side of the membrane, while the upstream side obtains low-concentration lean gas.

VOCs Organic Gas Comprehensive Recovery Membrane - Basic Principle

Utilizing the principle of the separation membrane preferentially permeating organic gases and retaining other inert gases, the separation of organic gases from other gases is achieved. High-concentration organic gases are recovered through condensation, achieving purified exhaust gas, and simultaneously achieving the recovery and treatment of organic waste gas.

1) Selective adsorption of the substance to be separated on the membrane surface;

2) Components permeate through the membrane by diffusion;

3) Desorption from the downstream surface into the gas phase and separation from the membrane.

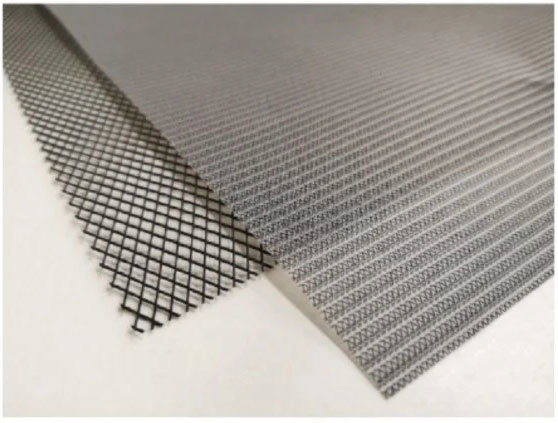

VOCs Organic Gas Comprehensive Recovery Membrane - Structure

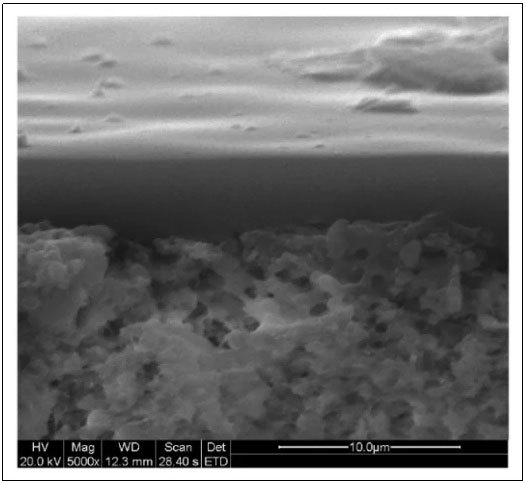

The comprehensive recovery membrane is composed of a non-woven fabric base membrane, an ultrafiltration intermediate membrane, and a surface dense separation membrane composite.

Membrane sheets and spacer nets are stacked and coiled to form a high-packing density roll-type VOCs recovery membrane module.

Separation layer: Dense polymer material, non-porous, solution-diffusion mechanism;

Base membrane: Porous polymer material, good compatibility, high bonding strength.

Advantages of VOCs Organic Gas Comprehensive Recovery Membrane I: High Performance

High-Polymer Flexible Anti-Static Conductive Net

The high-polymer flexible anti-static conductive net developed by the company, applied in the roll-type VOCs recovery membrane module, can efficiently and promptly discharge the static electricity generated during the operation of the module, preventing explosions and improving the safety of equipment operation. This conductive net features permanent conductivity, abrasion resistance, oxidation resistance, corrosion resistance, and non-membrane damage.

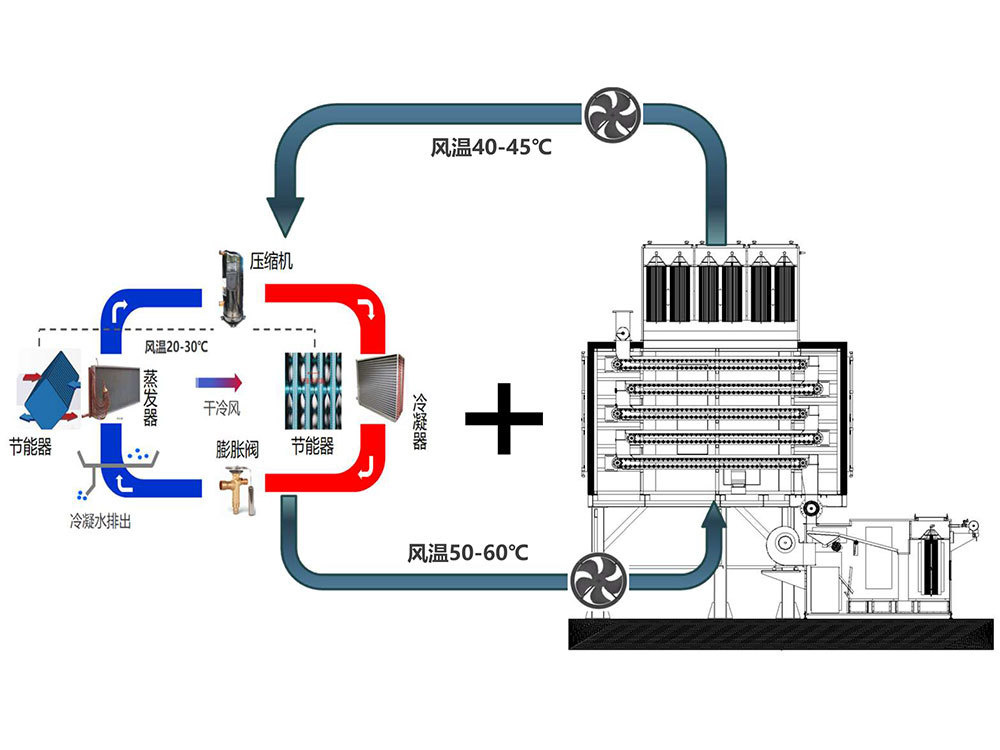

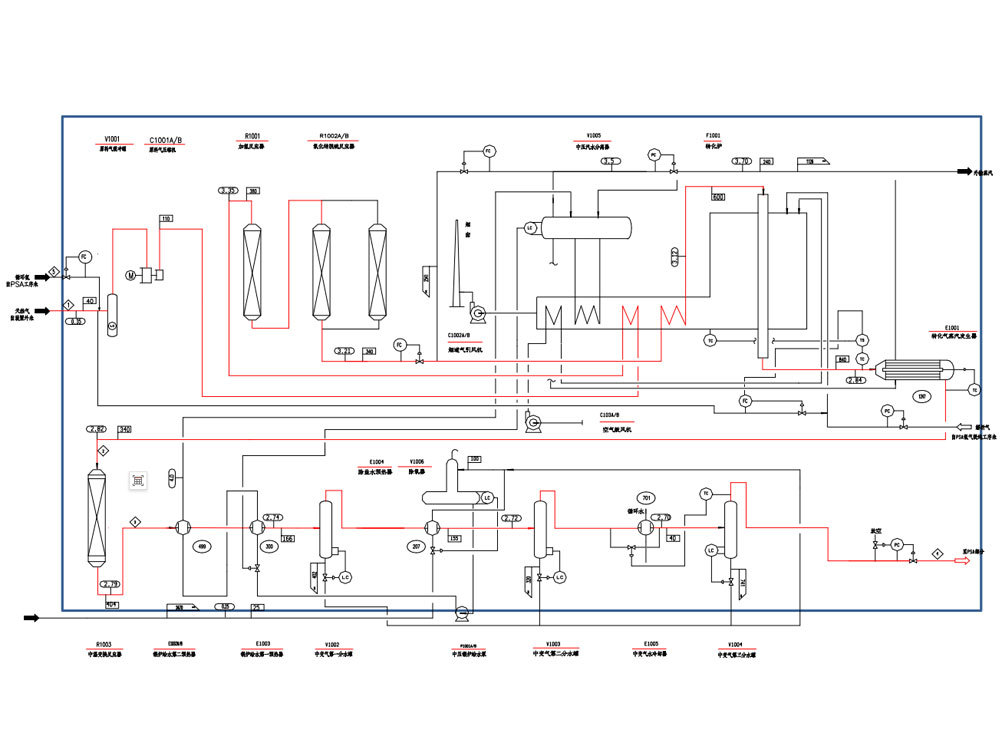

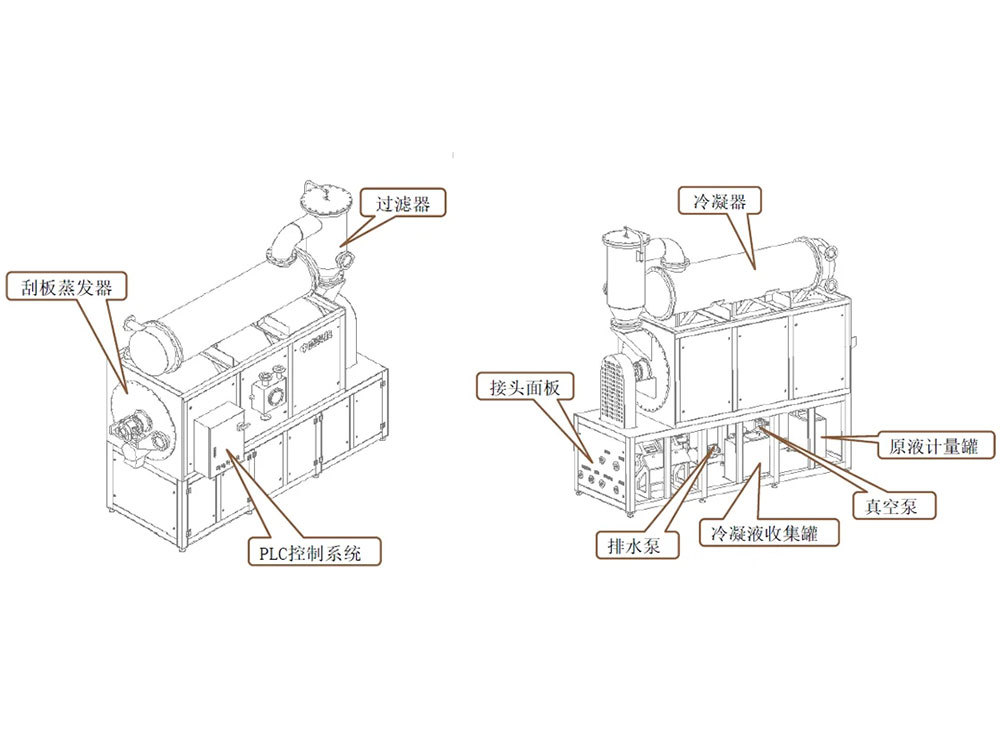

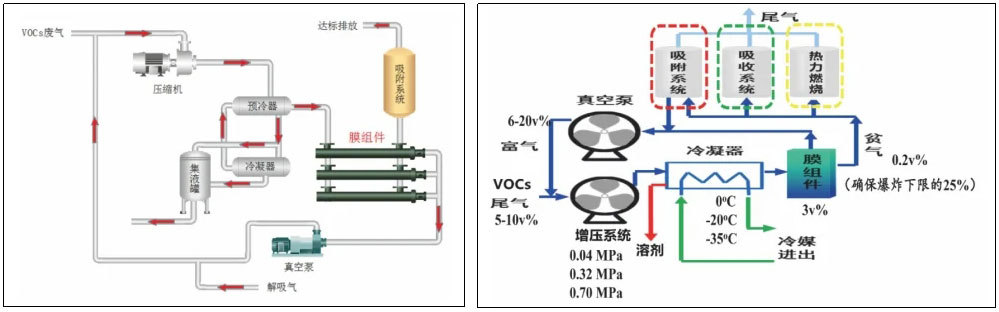

VOCs Organic Gas Comprehensive Recovery Membrane - Process Flow

VOCs waste gas with a certain concentration is pressurized and enters the condensation unit. The condensate is collected in a collection tank, and the uncondensed gas enters the membrane separation module. VOCs components are preferentially adsorbed on the membrane surface. A vacuum is maintained on the permeation side to maintain a negative pressure environment. Under the pressure difference on both sides of the membrane, VOCs components permeate through the membrane at a faster rate, and the concentration is enriched on the downstream side. This concentrated gas returns to the front end for continuous condensation coupling. The lean gas on the membrane permeate side enters the adsorption system, where VOCs components are captured by the adsorbent, and the waste gas concentration is further reduced. After meeting the emission standards, it is directly discharged into the atmosphere. At intervals, the adsorption system needs to be desorbed, and the desorbed gas also returns to the front end for coupled processing.

VOCs Organic Gas Comprehensive Recovery Membrane - Process Advantages

Excellent membrane performance: High concentration factor, large processing capacity, long lifespan, strong swelling resistance, anti-static, the membrane system plays a bridging role, on the one hand recovering and enriching the organic components in the uncondensed gas, significantly improving the condensation temperature, and reducing energy consumption; on the other hand, reducing the difficulty and load of reaching the standard treatment;

High efficiency and energy saving: Compared with traditional deep cold and adsorption processes, it can save about 20% energy;

Safe and stable: The membrane unit plays a bridging role, enhancing the condensation effect in the front stage and reducing the difficulty and load of adsorption in the later stage; each process unit is in a comfortable and safe operating range;

High recovery rate: VOCs recovery rate is no less than 97%;

Simple operation: Operated and controlled by PLC, with multiple alarm interlocks, high degree of automation.

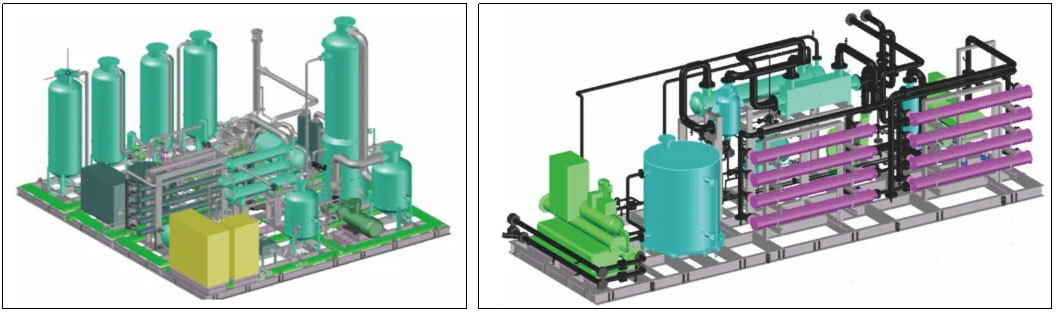

VOCs Organic Gas Comprehensive Recovery Membrane - Customized Engineering Design and Manufacturing

The company has a group of experienced designers in the membrane equipment industry, covering various professions such as process, piping, equipment, electrical, and automation control. Using mainstream engineering design software tools, it has a complete design management system.

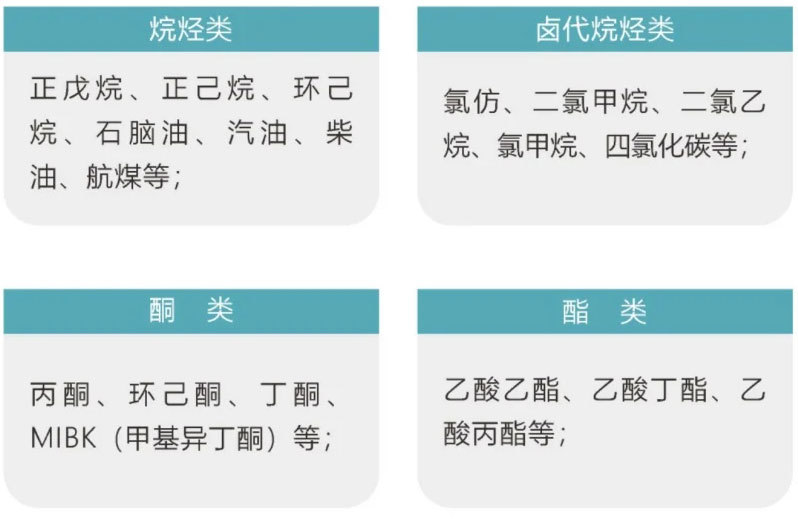

VOCs Organic Gas Comprehensive Recovery Membrane - Application Scenarios

VOCs Organic Gas Comprehensive Recovery Membrane - Application System

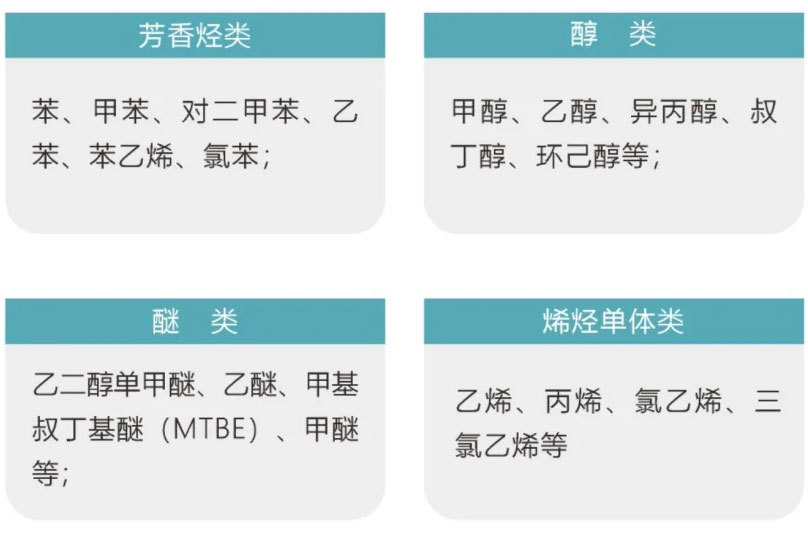

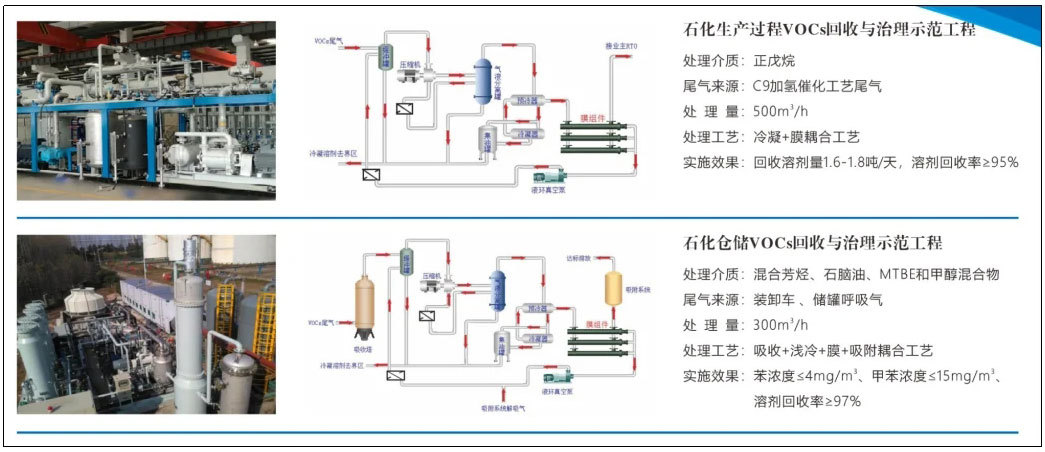

VOCs Organic Gas Comprehensive Recovery Membrane - Demonstration Project

Keywords:

VOC gas separation membrane