Product series

Contact us

Phone: +86-5065741650

Manager Wang

Email: 15065709046@163.com

Address: No. 10, District 1, 300 Changjiang Road, Yantai Economic and Technological Development Zone

Helium separation/purification

A technology-based enterprise focusing on industrial gas separation and purification with gas separation membrane as the core technology

- Commodity name: Helium separation/purification

Product details

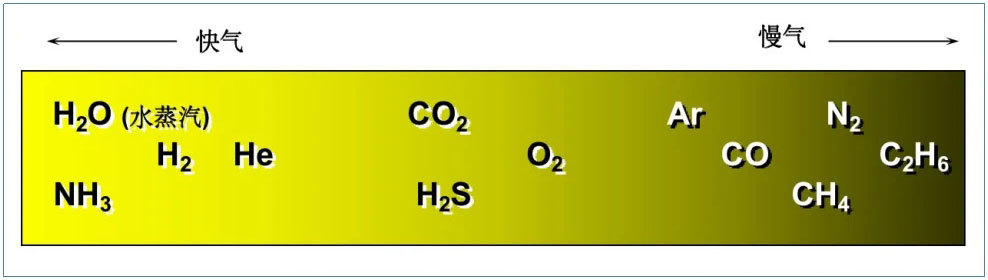

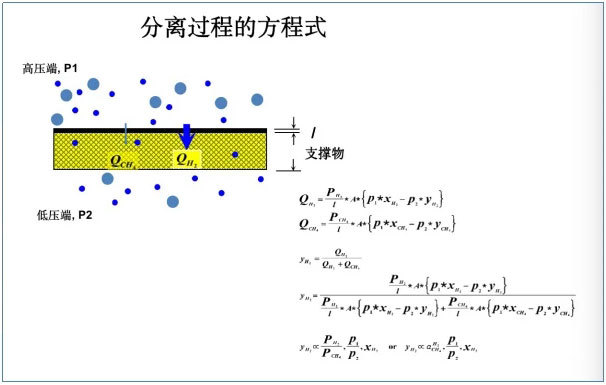

Gas separation membrane working principle

The working principle of membrane separation systems is to use a polymer membrane (usually polyimide) to selectively "filter" the feed gas to achieve separation. When two or more gases are mixed and pass through the polymer membrane, the difference in the solubility and diffusion coefficients of each gas component in the polymer leads to different permeation rates through the membrane wall. This allows the gas to be divided into "fast gases" (such as H 2 O, H 2 , He, etc.) and "slow gases" (such as N 2 , CH 4 and other hydrocarbons). Under the action of the driving force - the partial pressure difference of the corresponding components on both sides of the membrane, the fast gas with a relatively high permeation rate preferentially permeates through the membrane wall and is enriched on the low-pressure permeation side, while the gas with a relatively slow permeation rate is enriched on the high-pressure retention side.

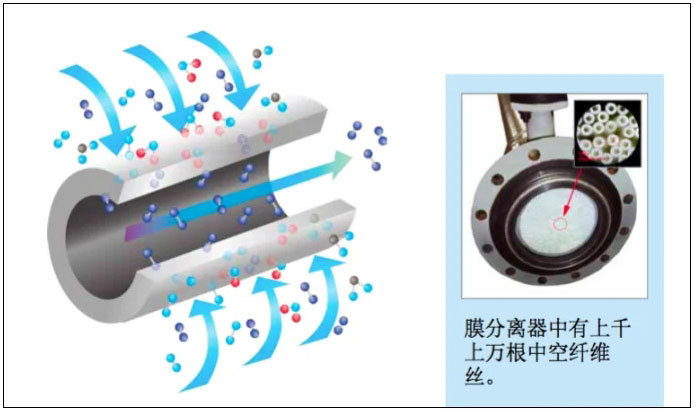

A typical membrane separator contains tens of thousands of fibers, sealed at both ends with epoxy resin. The ends of the fiber bundle are cut to expose the fiber pores at both ends, allowing gas to move from one end to the other. The fiber bundle is enclosed in a suitable housing. This housing protects the fibers and guides the correct gas flow.

Gas molecules permeate through the thin walls of the membrane fibers driven by different partial pressures. Factors affecting the permeability include solubility, diffusion rate, gas-polymer coordination, and the permeation rate of different gas components. The greater the difference in permeation rate, the better the separation efficiency.

Description of gas separation membrane performance

The core technology of all types of membranes used for gas separation is the modified polymer material with different components added. The principle of gas separation is the same. The performance of the membrane depends on the membrane material formula and production process of each manufacturer. Therefore, different membranes have different separation efficiencies, different pressure resistance, and different service lives.

Generally, the performance of a membrane can be described by gas production, recovery rate, and membrane life:

1) Gas production: The amount of product gas that a single membrane can produce;

2) Recovery rate: The percentage of the ratio of the yield of the target product gas to the content of the same component in the raw gas. A high recovery rate means that less raw gas is needed to obtain the same amount of product gas, making the operation more economical;

3) Membrane life: The durability of the membrane is related to many factors, including the membrane material itself, the rationality of the separation system design, and operation and maintenance.

The performance of the membrane is also related to many factors such as the purity of the product gas produced, the operating temperature, and the operating pressure. For air separation membranes for nitrogen production, the nitrogen recovery rate decreases with increasing operating temperature and slightly increases with increasing operating pressure, while the membrane production increases with increasing temperature and pressure. Therefore, the membrane must operate at a certain temperature and pressure to achieve optimal operating results.

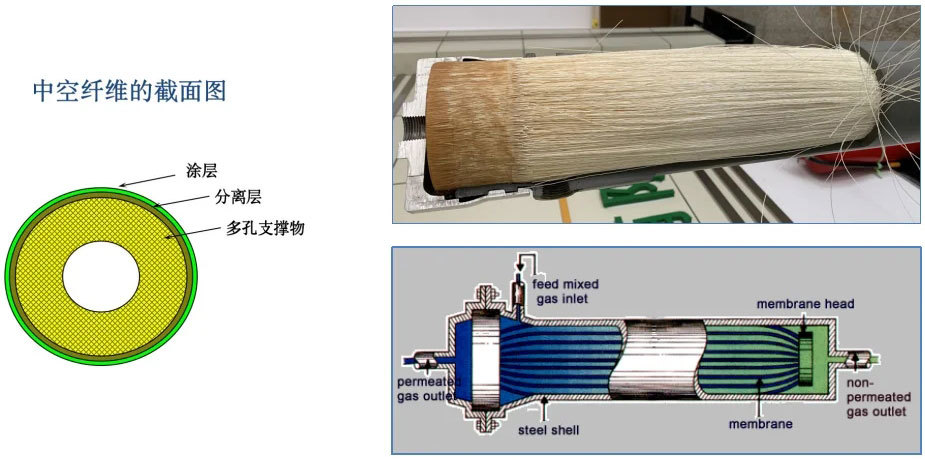

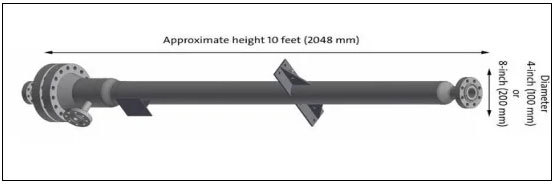

Gas separation membrane structure - hollow fiber membrane

The core component of the membrane separation system is a membrane separator similar to a shell and tube heat exchanger, in which tens of thousands of thin hollow fiber filaments are cast into a tube bundle and placed in a pressure-bearing shell. After the mixed gas enters the separator, it flows axially along one side of the fiber. The "fast gas" continuously permeates through the membrane wall and is enriched on the other side of the fiber, discharged through the permeate gas outlet, while the retained gas is discharged from the other end opposite to the gas inlet. Non-permeate gas outlet.

Gas separation membrane structure - membrane separator design and layout

● Each membrane bundle is easy to install into the pressure vessel

● Unidirectional and durable, different pressure sealing design

● Axially filled membrane filaments (instead of tightly wound configuration)

● Pressure vessels comply with: American standards, European standards, Russian standards, national standards, etc.

Membrane separator arrangement: series and parallel

● Series arrangement makes it easy to increase or decrease capacity and protect downstream separators

● Parallel configuration can be used for large flow rates to reduce the linear velocity in the membrane separator

Gas separation membrane structure - hollow fiber membrane

1. External pressure type: Process gas treatment membrane ---- PO and P2, P3 membranes, with more than 30 specifications from 2 to 8 inches.

Natural gas treatment membrane ------ The material is the same as P2, with dozens of specifications from 1 to 8 inches.

2. Internal pressure type: Air separation oxygen-enriched nitrogen membrane ------ P1, N1, 2, 3 and P3 membranes, with various specifications from 1 to 8 inches.

Characteristics of gas separation membrane system

Flexible: When unexpected changes occur in the plan or process, the membrane system provides operational flexibility. To meet increased production, more membrane separators can be added. If production needs to be reduced, closing the control valves of the separator can maintain the recovery rate and purity of the system. Multi-mode integration can obtain different purities and flow rates from the permeate side.

Compact: Suitable for small or crowded factories with minimal on-site installation time, cost, and potential construction errors. Short on-site preparation time, only simple concrete support platforms and utilities are required. The membrane system is a skid-mounted structure and is easy to move.

Effective and economical: In most applications, membrane systems have high recovery rates, with efficiencies of 80-95% for gases and carbon compounds. The operating pressure of the membrane system is basically the same as the pressure during refining, and no additional compression energy is needed for the separation process. Consumes very little steam (for temperature control), instrument gas, and purge nitrogen. This system is simple to start and stop, and the product gas does not need to be cooled and pre-treated.

Low maintenance: The membrane separator group has no moving parts to inspect, maintain, or replace. Under proper design, installation, and operating conditions, it is maintenance-free. However, attention should be paid to various process conditions during operation and some tolerable pollutants, such as liquid water, ammonia, hydrogen sulfide, hydrocarbons, and aromatics.

Long Lifespan: Sound design and structure ensure a long lifespan in petrochemical applications.

Advantages

|

Basic Performance |

Cryogenic Distillation |

Pressure Swing Adsorption |

Membrane Separation |

|

|

Principle |

Separation Medium |

|

Carbon Molecular Sieve |

Hollow Fiber Membrane |

|

Separation Principle |

Liquefy air and separate oxygen and nitrogen based on their different boiling points. |

Pressure adsorption, pressure swing desorption |

Pressure permeation (different permeabilities) |

|

|

Energy Consumption |

Energy-Consuming Components |

Compressor, expander, pressure pump, heating equipment |

Air Compressor |

Air Compressor |

|

Power Consumption KWh/Nm3 |

>0.62 |

0.4-0.6 (average) |

0.4-0.6 (average) |

|

|

Cost Yuan/Nm3 |

>0.6 |

0.3 |

0.2-0.3 |

|

|

Equipment Performance |

Nitrogen Production Nm3/h |

>500 |

<1000 |

10-5000 |

|

Nitrogen Purity % |

99-99.999 (stable) |

98-99.9 (fluctuating) |

95-99.9 (stable) |

|

|

Nitrogen Pressure MPa |

|

0.6 (fluctuation) |

0.6-1.8 |

|

|

Dew Point ℃ |

-60--70 |

-40 |

-60--70 |

|

|

Start-up Time |

20 hours |

30 minutes |

Within 10 minutes |

|

|

Maintenance |

Many moving parts, high maintenance, requires regular overhaul. |

Valve replacement is frequent, with maintenance and failure rates. |

No moving parts, minimal maintenance and servicing. |

|

|

Separation Medium Lifespan |

|

Domestic 5 years, imported 10 years. |

Hollow fiber 10+ years. |

|

|

Equipment Parameters |

Process Flow |

Complex |

General |

Simple |

|

Equipment Status |

Fixed only |

Fixed only |

Fixed, mobile, indoor and outdoor. |

|

|

Plant Area |

Maximum |

Smaller |

Small |

|

|

Cooling Water |

A lot |

None |

None |

|

|

Height |

Local 12 meters |

4-10 meters |

4 meters |

|

|

Electrical Capacity |

Maximum |

Smaller |

Minimum |

|

|

Dimensions |

Largest volume |

Smaller volume |

Smallest volume |

|

|

Capacity Expansion |

Difficult to expand capacity |

Difficult to expand capacity |

Separation membranes are assembled in parallel, easy to expand capacity. |

|

|

Random Start/Stop |

Cannot |

General |

Very easy |

|

|

Initial Investment |

High |

Low |

Lower |

|

|

Operators |

Requires specialized personnel |

Does not require specialized personnel |

Does not require specialized personnel |

|

|

Special Requirements |

Requires specialized installation, high installation cost |

None |

None |

|

|

Operating Costs |

Higher |

General |

Lower |

|

Industries and Applications of Gas Separation Membranes

▶ Hydrogen separation and recovery from synthesis ammonia purge gas

▶ Hydrogen separation and recovery from refinery gas

▶ Hydrogen purification from reformed gas

▶ H 2 /CO ratio adjustment and CO purification

▶ Hydrogen recovery from methanol tail gas

▶ Natural gas dehydration and acid gas removal (including carbon dioxide and hydrogen sulfide)

▶ Ammonia purification and enrichment in LNG flash gas

▶ Helium purification and enrichment in coal seam gas

▶ Helium purification and enrichment in various raw gases

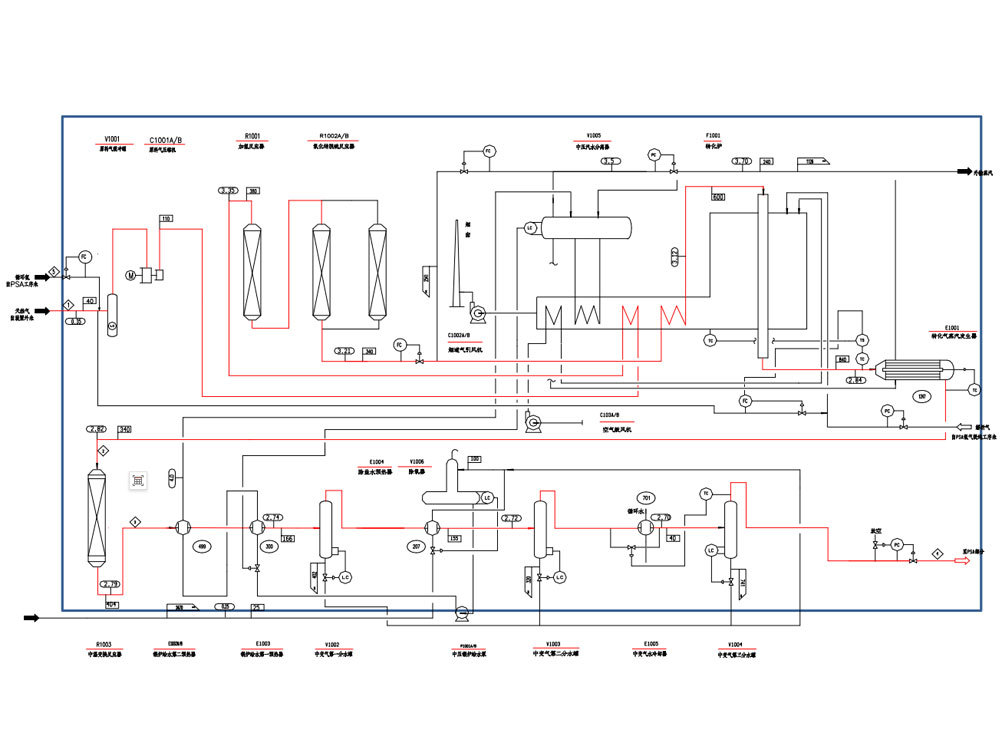

Application of membrane separation systems in ammonia plants

|

Scale Classification |

Helium reserves (Mm 3) |

Content Classification |

Helium content (volume%) |

|

Extra-large gas field |

≥100 |

Extra-rich helium gas field |

≥0.500 |

|

Large gas field |

50-100 |

Rich helium gas field |

0.150-0.500 |

|

Medium-sized gas field |

25-50 |

Helium-bearing gas field |

0.050-0.150 |

|

Small gas field |

5-25 |

Poor helium gas field |

0.005-0.050 |

|

Extra-small gas field |

<5 |

Extra-poor helium gas field |

<0.005 |

There are four main methods for helium preparation: natural gas separation, ammonia synthesis (helium separation and purification from tail gas in ammonia synthesis), air distillation, and uranium ore method. Among them, natural gas separation is currently the only industrialized method for obtaining helium. The helium content in natural gas can be as high as 7.5%, which is 15,000 times the helium content in air. Currently, all the discovered large-scale helium reserves in the world are associated gases from natural gas. According to the size of helium reserves in oil and gas fields, helium fields can be classified into extra-large, large, medium-sized, small, and extra-small gas fields based on scale; according to the size of helium content in oil and gas fields, helium fields can be classified into extra-rich, rich, poor, and extra-poor helium gas fields based on content. Based on this standard, the North Field in Qatar has a helium content of 0.04% and helium resources of 1.01 billion cubic meters, belonging to an extra-large helium-bearing gas field.

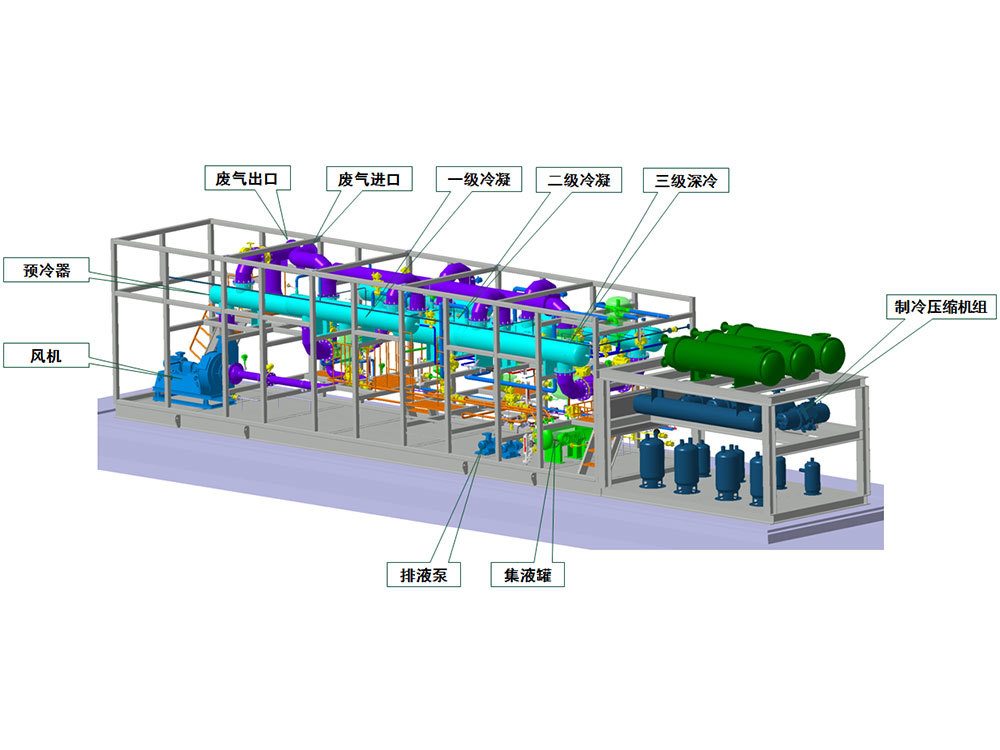

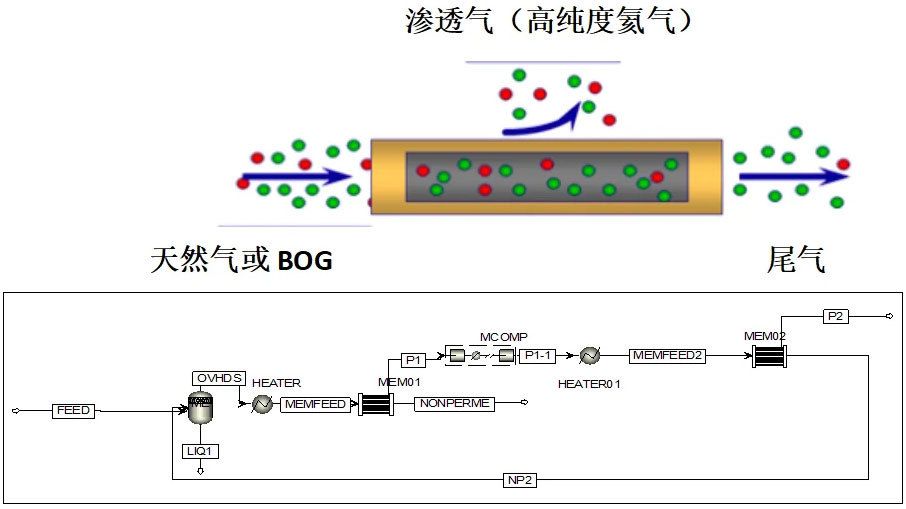

Helium Purification/Enrichment Membrane Engineering

Membrane permeation utilizes the different permeation properties of various gases such as helium, nitrogen, argon, and methane through the membrane to extract helium from natural gas.

If there are other impurities in the gas, such as H 2 , catalytic removal and other composite processes are also needed.

Keywords:

Helium separation/purification